Makino Inc

Mason, OH 45040

Vertical Machining Center suits small and large mold shops.

Model S56 utilizes 40 taper, 13,000 rpm spindle and can maintain positioning accuracies to within Ã-

Read More »

Horizontal Machining Center has pallet change time of 7 sec.

Utilizing out-of-cut technology to reduce part cycle times, model a61 has X-, Y-, and Z-axis travel of 28.7 x 25.6 x 28.7 in. and work zone of 32 x 36 in. Pallet size is 19.7 in., max load capacity is rated at 1,540 lbs, and rapid traverse and feedrate are 1,970 ipm. Using Geometric Intelligence servo control with Radical Mode, unit comes equipped with tool monitoring capabilities; 40-taper,...

Read More »

Machining Center handles turbine-blade cooling holes.

Model EDGE2S-5X, with sinker EDM technology and single tungsten-carbide electrode, uses electrode rotation and oil-based dielectric fluid. Offerings include 16-station automatic electrode changer, automatic pipe electrode guide, and MR rotating head, capable of Z-axis high-speed pulse machining at 396 ipm. Fixed table eliminates dielectric weight shift during machining, while rotary table can...

Read More »

Machining Center produces mid-sized aerospace components.

Model MAG3 Aerospace Machining Center provides 5-axis horizontal machining. With 9.843 ft X-travel selection, it is equipped with 30,000 rpm, 80 hp, core-cooled spindle. Unit is designed with C-axis behind A-axis rotary head, allowing tool to orient itself toward any position within hemisphere. A-axis allows Ã-

Read More »

VMC utilizes 40 taper, 13,000 rpm spindle.

The S33 Vertical Machining Center features heavy cast construction and is capable of maintaining positioning accuracies to within Ã-

Read More »

EDM Machine targets stamping die market.

The SP43 part-in/part-out production wire-cutting machine handles maximum workload of 1,760 lbs and is able to hold tolerances of Ã-

Read More »

EDM Machine comes with automatic tool changer.

Compact Edge3 Sinker EDM is suitable for use in plastic injection molding and forging die job shops. It measures 78 x 84 x 92.8 in., weighs 10,340 lb, and has 8, 16, or 32 station automatic electrode changer. Machine has XYZ axis of 18 x 12 x 12.8 in. with Z-axis jump speed of 400 ipm. Traverse speed is 400 ipm and cycle time jump rates are 393 ipm. Worktable allows for workpieces as large as...

Read More »

Machining Center has 50 taper spindle and 25.2 in. pallet.

Model a81 Horizontal Machining Center (HMC) diminishes out-of-cut time with ring-type, 40-tool magazine, automatic tool changer, with 1.7 second tool-to-tool change times. Capable of handling payloads to 3,300 lbs, it offers 10,000 rpm spindle equipped with 300 psi through-spindle coolant system. Traverse and cutting rates are 2,362 ipm. Model a81 is capable of simultaneous B-axis movement with...

Read More »

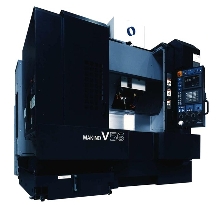

Vertical Machining Center is suitable for dies and molds.

V56 VMC machines dies for precision press dies, mold base of plastic molds, and forging dies. It virtually eliminates need to polish small and medium size dies and molds. It can handle workpieces as large as 41.3 x 28.3 x 17.7 in. weighing up to 1,760 lb. VMC has 40 taper, 20,000 rpm spindle, spindle core cooling, under race lubrication system, 0.000002 in. feedback system, and traverse and...

Read More »

Vertical Machining Center offers rapid set up and feed rates.

Model S33L VMC, with 40 x 18 in. working surface, utilizes 40 taper, 13,000 rpm spindle; Super Geometric Intelligence (SGL3) servo control; and axis configuration with no overhangs. It maintains positioning accuracies within Ã-

Read More »