New-M30 and -L50 Geometries for Radius Inserts in Automotive and Aerospace Sectors

-M30 geometry optimizes groove milling of steel and cast iron automotive parts. Available for size 11 inserts with radius dimensions from 1.5 to 3.0 mm (0.059 to 0.118 in). -L50 geometry is offered for size 11 inserts with radius dimensions from 3.0 mm to 6.3 mm.

Read More »

New MultiStrike Tungsten Electrodes are Radio-toxic Free

Contains a mix of rare earth stabilizing compounds without thoria. Reduces the amount of stock and purchasing requisitions by using one type of Tungsten Electrode to weld all materials. MultiStrikes® are used for welding aluminium with the AC process, as well as steels and alloys with the DC process.

Read More »

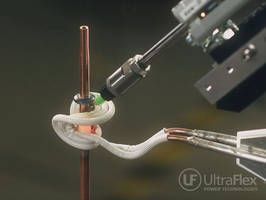

New Dragon 15 Robotic Brazing System is Capable of Brazing Multiple Joints

Features integrated induction coil mounted onto the robotic arm. Can work with 15 KW induction system and a wire feeder. Capable of programming wire feeder to start when the heating temperature had been reached.

Read More »

Mobile Induction Generators feature intuitive user interface.

Depending on model, PICO-S, PICO-M, and PICO-L can be configured as medium frequency or high frequency energy sources from 5–150 kW. Units feature continuous, tap, and timer modes, as well as power, current, and temperature control. Plug-and-play generators are equipped with memory for up to 50 recipes and 8 individual timers with up to 600 sec runtime each. Typical applications include...

Read More »

Hot Forging Process

Check out this white paper to learn about the benefits of hot forging.

Read More »Yardley Provides Custom Threaded Metal Inserts to RC Jet Boat Manufacturer

Yardley Products, a manufacturer of precision engineered threaded metal inserts for a wide range of fastening applications, recently supplied a custom order of thermal threaded inserts to Streamline RC, a US-based hobby-grade RC Jet Boat manufacturer. Yardley operates a range of multi-spindle, single-spindle and secondary machines to produce complex parts and custom solutions. This capability...

Read More »

Wire Feeder suits heavy and general fab applications.

Featuring flexible, modular design, Flex FeedÃ-® 84 delivers consistent feeding over long conduit runs with large-diameter wires up to 3/32 in. or cored wires up to .120 in. Single-bench, dual-bench, and boom-mount configurations can be converted as workspace requirements change. Patented MaxTracÃ-® wire drive has rugged, cast-aluminum feed plate that protects wire and ensures consistent...

Read More »Indexable Inserts, Grades enhance turning and milling options.

Designed for rough forging and castings, HR2 chip breaker featuresÃ- positive, stable geometry. Single-sided inserts are suited for working in steels, cast irons, and stainless steels. Also available, double-sided NMR chipÃ- breakers are designed for stainless steel operations. Wiper inserts W-FM and W-NM have positive front land for smooth machining. While T9226 grade suits heavy...

Read More »

Low Manganese Wires help meet environmental regulations.

In addition to low manganese levels, FabCOÃ-® Element 71C and 71M offer optimized out-of-position capabilities, enabling welding operators to create quality welds regardless of joint placement. Gas-shielded flux-cored wires produce low spatter levels and have fast-freezing, easy-to-remove slag. Available in diameters of 0.045, 0.052, and 1/16 in. on 33 lb fiber spools, Element 71C is...

Read More »

HF Welding Simplified for Diverse API Product Manufacturer

One of the World's largest suppliers of ERW pipes has completed the installation of a new 800kW HAZControl™ Technology Dual (induction/contact) Solid State HF Welder at one of their North American facilities. Dedicated to serving the growing demand of the global oil and gas industry, the North American producer chose Thermatool to meet API standards required by their customers. The organization...

Read More »New Laser Capabilities Recently Purchased

Weaver & Sons, Inc. is proud to announce the purchase of a new Amada Laser Cutting System.Ã- This new system will not only add greater reliability to our current laser cutting capabilities, but will also add greater speed and automation which we believe will translate into a better value to our customers, says Dyron Overton - President & General Manager.Ã- We have also added robotic...

Read More »

DoorKing's 1601 Lane Barrier Provides a Higher Level of Traffic Control for Less

DoorKing is proud to introduce an easy add-on to its 1601 Barrier Gate Operator: The 1601 Traffic Lane Barrier. The barrier gate provides greater traffic control while eliminating the need for bollards or crash beams. Check out this video to learn more.

Read More »