MIG (GMAW) Wire meets global pipe welding industry demands.

PipelinerÃ-® 80Ni1 is designed for semi-automatic or automatic welding of root, hot, fill, and cap passes on up to X80 grade pipe and root passes on up to X100 grade pipe. Capable of producing impact properties of 69-95 J at -50Ã-

Read More »

Robotic MIG Gun features air- and water-cooled design.

TOUGH GUN I.C.E.(TM) (Integrated Cooling Enhancer) Robotic MIG Gun circulates water at nozzle and has SS water lines running along durable air-cooled gooseneck. External water lines run independently of power cable and shut-off valves at I.C.E. connections, so maintenance downtime is limited. Device provides 550 A capacity at 60% duty cycle with mixed gases and supports wide range of metal...

Read More »

MIG Welding Guns suit light- to medium-duty applications.

Model TGX(TM) Semi-Automatic MIG Guns are available in XL 400 A, XL300 A, XS 300 A, XS 260 A, and XS 180 A versions. They feature black polymer armored-style gooseneck, gray gun handles, black triggers, and rear handle. Available in standard lengths of 10, 12, and 15 ft, guns include LOCK(TM) Retaining Heads with Dual Taper Technology to maximize life of consumables and help them run cooler....

Read More »

Low Hydrogen Stick Electrode is suited for offshore welding.

Used for all-position welding of carbon-manganese, chromium-molybdenum, and low alloy steels, ExcaliburÃ-® 10018-D2 MR meets NACE requirements for corrosion resistance necessary for offshore and subsea welding of pipe carrying H2S or sour gas. Specified chromium-molybdenum steels include AISI 4130, 4140, and 8630 as well as ASTM A182 and A336 Grades F22. Electrode is optimized for arc...

Read More »

How to Choose the Right Vacuum Chamber

To learn more about avoiding the pitfalls in choosing a vacuum chamber manufacturer and KTC's expertise in this area, download this white paper now.

Read More »

Shipyard Improves Welding Process wtih Automation

It has long been considered that the most productive and cost effective welding position within the shipbuilding industry is the flat position (PA). To satisfy this, great emphasis is put in at the design stage to maximize the use of this position. However, even when adopting this philosophy, welding has to be carried out in a variety of other positions. Many shipyards have found major benefits...

Read More »

Welding Helmets deflect heat for extended wear.

Arc Armor(TM) Titanium 1600 has 16 in.Ã-² shade No. 10 passive lens, Titanium 7300 features 7.22 in.Ã-² viewing area and shades No. 8-13, 20 oz Titanium 9400 has 9.22 in.Ã-² viewing area and same shades, and Titanium 9400i features 9.22 in.Ã-² viewing area and lens that flips up to expose integrated grinding shield. Latter 3 auto-darkening models (9400/9400i/7300) feature...

Read More »

Conversion Parts help switch between MIG, flux-cored welding.

Centerfire(TM) conversion parts enable companies to switch between MIG and self-shielded flux-cored welding without gun changeover. Units allow Q-Gun(TM) with Centerfire(TM) consumables to be converted to accommodate either process. Using parts, welding operator can replace MIG nozzle, which directs shielding gas, with contact tip holder and insulator, since shielding gas is not needed for...

Read More »Safety Glasses are intended for welding applications.

In addition to 3 frame colors, Arc Armor(TM) ANSI-compliant safety glasses offer choice of clear or shade 5.0 lenses. Form-fitting orbital eye coverage and rubber ear pads provide wearer comfort, while soft foam eye guards keep out dust and perspiration. Lenses are shatterproof and feature anti-scratch coating, and shade 5.0 lens, suited for plasma or oxy-fuel cutting, also features reflective...

Read More »

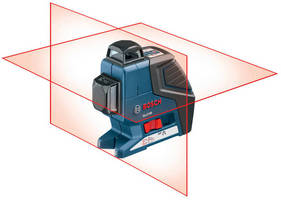

Dual-Plane Line Laser projects over 360 degree range.

Able to project constant lines on vertical and horizontal planes, GLL2-80 is suited for alignment and leveling applications. Self-leveling device can be switched between dual-plane and vertical- or horizontal-only modes and employs proprietary Cone Mirror Technology, which reflects laser beam to project laser lines over 360Ã-

Read More »

MIG Welding System accommodates multiple wire types.

Using benchtop feeder, Invision(TM) MPa Plus System with Alumination(TM) technology provides both push-pull and standard push wire feeding capabilities, as well as MIG/pulsed MIG welding outputs for heavy industrial applications that use aluminum and second wire type or wire diameter at single welding station. System includes Invision 352 MPa welder with built-in pulsed MIG programs, D-74 MPa...

Read More »

Triad's JSU Series of Power Supplies Provide Robust, Low Cost Solutions

Triad Magnetics is an established leader in power supply innovation, offering product lines that span a wide range of diverse industries and applications. Adding to their long list of successful product launches, Triad announces the release of the new cutting-edge JSU Series of power supplies. To learn about all of its advantages and advanced features, see our video.

Read More »