Bulk Bag Unloader optimizes discharge via controlled vibration.

Using controlled vibration, Model 820 reliably dischargesÃ- bulk bagÃ- contents. Model 82-SCM Bag Spout Clamping Mechanism, included,Ã- allows unrestricted access to bag's discharge spout and attachment to process interface transition equipment in clean and dust-tight manner. Dust Collection System is available to assist in deflating empty bag, and Bag Lifting Racks automatically...

Read More »Cat Lift Trucks Kicks off Its Ninth Year as Official Lift Truck Provider of 2013 Houston Livestock Show and Rodeo(TM)

More than 100 CatÃ-® lift trucks will keep world's largest livestock show and rodeo running HOUSTON - More than 2 million people and 30,000 animals are expected at Reliant Park for the 2013 Houston Livestock Show and Rodeo(TM) in February and March, and behind the scenes Cat Lift Trucks will provide the equipment and expertise, including more than 100 lift trucks, needed to prepare for the...

Read More »

Continuous Motion Uncaser has 70 case/min capacity.

PikMore Uncaser features gripper heads that revolve around center carousel to lift empty glass bottles from their cases. Bottles are then placed on conveyor as they leave machine. Continuous motion machine includes graphic operator interface screen that enables mostly automatic operation. Programmed for auto lubrication, product also times all operations through trigger on main carousel, and is...

Read More »

Single Trip Bulk Bag Unloader from Spiroflow Systems for Low Value or Hazardous Products

CHARLOTTE, NORTH CAROLINA - A single trip bulk bag discharger from Spiroflow Systems, Inc. is ideal for plants that require a rapid, dust-free economic and controllable method of emptying low value or hazardous products. The proven 'Spiroflow' Model T4 Single Trip Bulk Bag Discharger discharges flat bottom disposable bags without a bottom spout and does not result in any product wastage or...

Read More »

EMI/RFI Shielding Considerations for Electric Vehicles

This white paper provides an overview into EMI/RFI shielding considerations for electric vehicles.

Read More »

Bulk Bag Unloader has flexible screw conveyor.

Single-Trip Bulk Bag Unloader conveys material at any angle to downstream processing, storage, or packaging equipment. Product features 4-bladed bag-piercing knife that cuts bag bottom from seam-to-seam after single-use bulk bags are lowered with forklift or plant hoist. Bag bottom self-seals against gasket affixed to rim of unit's hopper, and material discharges through hole in center of gasket....

Read More »

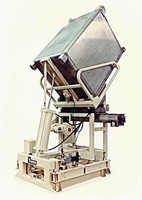

Bulk Bag Conditioning System is integral to unloader.

Bulk Bag Conditioner-Unloader System loosens bulk solid material solidified during storage and shipment, allowing material to discharge through bag spout. While integral configuration of conditioner eliminates time, labor, and equipment needed for separate loading of bulk bags into standalone conditioner, design also minimizes floor space requirements. System employs 2 hydraulic rams with...

Read More »

Compact Loader can load/unload trays and conveyors.

Weighing less than ton, Model DS1100-TD can be moved from one point of use to another with pallet jack. It can load in less than 2 sec and cycle in less than 10 sec, and transfer parts to secondary operations such as washing, inspection, or marking. Featuring 2 drawers, 7-axis robot can handle tray of up to 18 x 24 in. Clean room compatibility makes it suitable for assembly, medical, electronics,...

Read More »Loading Automation Inc. Introduces the Automated Truck Loading System (ATLS) to North American Market

WILMINGTON, N.C., May 7 -- Loading Automation, Inc., a premiere Systems Integrator specializing in automated vehicle loading systems, is proud to announce their partnership with Paco Corp., a Canadian based equipment manufacturer. Paco has developed and proven the Automated Trailer Loading System (ATLS) which is capable of loading and unloading all standard, non-dedicated over-the-road...

Read More »

Bag Dump System incorporates delumper processor.

Designed to facilitate manual opening of small- to medium-sized bags without creating dusty environment, DELUMPER BAGSTATION unloads, de-agglomerates, and freshens lumpy bagged solids while introducing them into production process. DELUMPER crusher reduces lumps and agglomerates to free flowing state with positive, one pass crushing action. Along with air filtration system, options include...

Read More »

Portable Bin Unloader features loss-in-weight feeding.

Loss-In-Weight Portable Bin Unloaders allow accurate discharging and metering of material stored and transported in side or bottom discharge portable bins. Weighing is done through low deflection, non-wearing Force Measurement Suspension System (FMSS)flexure scale which measures vertical loading and can take high load directed overloads. FMSS scale design uses counterweights to negate tare weight...

Read More »

Locon Sensors Withstand Extreme Temperatures

Locon Sensor Systems offer robust sensor solutions for even the most severe environmental conditions. Their line of high-temp inductive sensors and their cylindrical photoelectric series can operate in temperatures up to 250 degrees Celsius. See our video to learn more.

Read More »