Bulk Bag Unloader offers variable flow rate.

Bulk Bag Unloader provides continuous discharge of material from bulk bags with ability to regulate or stop flow in accordance with system requirements. Two vibrators mounted on opposite sides of hopper create movement of material through integral sealed feed tube. When vibration is stopped, bag discharge and material feed immediately cease without need for additional valves. Unloader can be run...

Read More »Bulk Bag Unloaders offer total dust containment.

Eliminating upper frame components to lift and/or position bag, Half Frame Bulk Bag Unloaders utilize forklift or plant hoist instead. Spout-LockÃ-® clamp ring positioned atop pneumatically actuated Tele-TubeÃ-® allows dust-tight connections and unrestricted flow between bag spout and hopper. Flow-FlexerÃ-® bag activators raise and lower opposite bottom edges of bag at timed...

Read More »

Machine unloads unstable plastic bottles from reshippers.

Eliminating need for case erecting machinery, Model M49 automatically feeds cases, unloads containers, and discharges them in bulk for conveyor transport to orienter or unscrambler. Featuring heavy channel steel frame and motor-powered side belts, machine handles case sizes from 9 x 8 x 5 in. to 26 x 15 x 13 in. and unloads many different case styles. Model M49 replaces manual labor required to...

Read More »

Truck Unloader speeds material discharge process.

Featuring hydraulically adjustable discharge height, low-profile truck unloader utilizes hinged, self-cleaning ramps that hydraulically rise to vertical position. Unit has transport position under 12 ft wide and 72 in. wide conveyor belt with discharge hood that directs material onto smaller-width belt. Offering up to 1,500 TPH capacity with no spillage, unit can transfer 25 tons of 100 PCF...

Read More »

Hemp: An Eco-friendly Substitute for Cotton and Petroleum-based Synthetics

To learn more about hemp's history, composition, performance, and its sustainability and cost, download this white paper now.

Read More »

Packaging Machine combines case packing and unpacking.

Featuring servo-operated, robotic-style transfer head, Model 360 delivers two separate actions simultaneously. As head lowers into case, filled bottles are packed, and empty bottles are gripped for unloading. As head reaches conveyor, empty containers are deposited for transfer to filling, and additional filled containers are picked up for packing. Occupying 56 sq ft of floor space, Model 360...

Read More »

Bulk Bag Discharger Module eliminates contamination.

Bag spout untie module, Model E3 engages bulk bag discharge spout with manually-operated compression clamp to prevent foreign material from entering downstream process. It also eliminates dust escaping into plant atmosphere during discharge cycle by extracting dust-laden, displaced air from receiving hopper to dust collector. To assure complete product discharge, E3 elongates discharge spout of...

Read More »

Vacuum Extractor facilitates unattended operation.

Suited for twin-spindle CNC lathes, VacXtract unloading device removes work pieces through rear of right spindle in under 2 seconds, allowing left spindle to continue working during unloading cycle. In addition to shop air, system receives power from lathe's own power supply and is programmed via lathe's CNC control. At proper moment, it creates vacuum inside spindle bore, gently extracting...

Read More »

Modular System unloads bulk bags and fills drums.

Material Master(TM) safely unloads bulk bags of non-free flowing powders and fills drums to programmed set point. System includes bulk bag discharger with flow enhancement, dust control, and discharge gate technology. It also incorporates inclined screw conveyor with variable-frequency drive, rotating sieve with magnet, dust-tight gain-in-weight drum filler, and auto/manual system controls....

Read More »Auto Loading System suits centerless grinding machines.

Auto Loading and Unloading System handles shafts ranging in length from 150 mm up to 1 m. Shafts are kept on inclined table where pneumatic cylinder feeds one shaft at a time to belt conveyor, which then feeds shaft to centerless grinding machine. After grinding, unloading belt conveyor takes shaft out and turns it around using transfer station. Shaft is then fed to another belt conveyor for...

Read More »

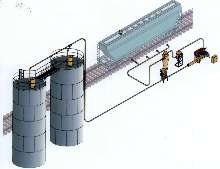

Unload System offers conveying rates up to 40,000 lb/hr.

Single-blower, vacuum-pressure, Rail Unload System unloads powder, pellets, and granular material from railcars. One blower powers both sides of system, drawing material from railcar to Premier Cyclone to separate product from conveying air. Aerolock(TM) rotary valve meters product into pressure side of system for final delivery to storage tank. PLC control provides manual start/stop operation,...

Read More »

Standex Engraving Mold-Tech Offers Nickel Shell Capabilities on a Global Scale

Standex Engraving Mold-Tech is the premier, global supplier for mold texturing and surface finishing. With a full range of services, Standex Engraving Mold-Tech is also the only nickel shell supplier producing in three global locations. See our video to learn more.

Read More »