Bulk Bag Unloader features modular construction.

Custom-engineered to accommodate specific application requirements, Modular MATERIAL MASTER(TM) incorporates Flo-Lock(TM) discharge spout closure system that allows material flow to be stopped during discharge. It also utilizes Flo-Master(TM) bag massagers to promote material discharge and round, dust-tight Seal-Master(TM) bag spout access chamber with gull wing doors to ensure operator access to...

Read More »

Bulk Bag Unloader offers mobility.

Forklift-loaded Bulk Bag Unloader, combined with Series 400 Helix(TM) conveyor and mobile frame, results in system that can be moved to various processing stations for charging as needed. Transfer rates of 3-4 cfm are possible. Adjustable frame handles variable bag heights. Optional bag agitator along with vibrator and level sensor help assure efficient transfer of material.

Read More »

Bulk Bag Unloader features loss-in-weight batching system.

Modular Forceflo, in conjunction with receiving hopper's integral agitator and feed auger, consistently feeds material from bulk bag into process equipment. Integral load cells and control package provide loss-in-weight batching capabilities for material direct from bulk bag. Controls retain weight information when replacing empty bag with filled bag and will automatically dispense proper amount...

Read More »

Bulk Bag Discharger handles bags up to 4,000 lb.

Bulk Bag Discharger uses forklift truck for loading and unloading bulk bags from discharging frame. Framework is 4 in. sq tubular washdown construction. All tube ends are capped, angled, or rounded to promote drainage and eliminate pockets where material or water can accumulate. Bridgbuster massage paddles ensure complete material discharge from bag. Polished 304 SS unite box mounts directly to...

Read More »Converting Services 101: Types of Services, Applications, and How to Select a Provider

This ebook provides an in-depth guide to converting services.

Read More »

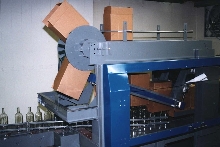

Decaser handles cases of wine and distilled spirits.

Model 49X automatically unloads and single files reverse tapered glass bottles from club store display cases at up to 50 cases/min. Single filing section with series of multiple tabletop chains separate bottles while maintaining bottle control and stability. As cases are lifted from bottles, they are transported by motorized belts backed by duro-soft rollers that adjust to variations in case and...

Read More »

Single Magazine Unloader offers 50-board capacity.

Model F1300 unloads one magazine of circuit boards (which can be accessed from back of unit) into production line. Product buffers 50 boards at 0.394 in. pitch, is fully programmable, and has independent motor controlled belt section with open transfer technology. Magnetically coupled break-away pusher assembly eliminates board damage. Unit accommodates boards with lengths and widths from 2-20...

Read More »

Bulk Bag Unloader disassembles without tools.

Used with company's compressed air powered vacuum conveyors, Bulk Bag Unloader eliminates dust contamination during material handling processes. Fully contained, pneumatically operated unit offers all contact surfaces in 316 SS. With bulk bag elevated above station, spout of bag is attached to inflatable seal that provides dust-free connection. Structure of unit eliminates need for material...

Read More »

Case Unloader handles size variations.

Model 49 decaser automatically unloads glass or plastic bottles and containers from necks-down reshipper cases. It single files containers and uprights emptied cases. Cases are conveyed to packer at speeds up to 75 cases per min. Roller system uses automatic tensioner combined with soft compression rollers. Case turnover offers finger-style grippers that bend to hold cases securely during 180Ã-

Read More »

Oilfield Improvements® Wheeled Rod Guide® Couplings Celebrate 35th Anniversary

For over 35 years our Wheeled Rod Guide Couplings, have been at work in oil fields across the globe. Our products are engineered to extend the service life of sucker rods and tubing, delivering cutting-edge innovation that enhances oilfield operation, maximizes output, and enhancing overall operations. To learn about the advantages of using Wheeled Rod Guide Couplings in your wells, see our video.

Read More »