Workholding Systems are customized to maximize throughput.

Tombstones are offered in steel for high rigidity or cast iron for vibration damping. Vises mounted on tombstones are designed for close tolerances. Hydraulic-actuated fixtures feature internal hydraulic lines providing clean, safe operation. Workholding systems are ergonomically designed and include pre-clamping methods for easy loading and unloading of parts.

Read More »

Welding Gripper replaces two models with one.

Model WPG-250 universal, 3-jaw, self-centering gripper has clamping range of .38-15 in. Mountable on any make of positioner, its smooth close/open action uses lever to firmly lock and release workpiece. Ruggedly constructed, unit provides minimal reduction in positioner capacity.

Read More »

Towers provide rigid part holding for machining centers.

Compact CarvLock(TM) HD 8-station manual and hydraulic towers have quick-change machinable jaws that mount on ductile iron base. Clamping stations on manual tower produce 5556 lbs of clamping force at 70 lb-ft of torque, with repeatable clamping to .001 in. Hydraulic model produces up to 7800 lb of clamping force. Both are easily converted from manual to hydraulic or vise versa. Manual tower is...

Read More »

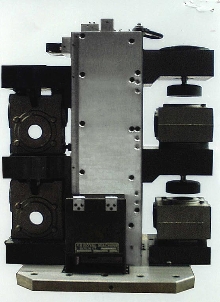

Hydraulic Fixtures maximize capability of HMCs.

Hydraulic Custom Fixtures handle multiple parts per side for first or secondary operation on horizontal machining centers (HMCs). They can handle large and difficult parts resulting in reduction of set-up and production times. Depending on required system, multiple column configurations are available.

Read More »

Tool Locking Fixture protects tool holder shanks.

Nylon sleeve in tool holder locking fixture protects ground steel taper shanks from being damaged when tools are mounted or removed. Locking fixtures can also be used to eliminate on-spindle tool changes that can cause damage to high-speed spindles. Fixtures are available in 30, 40, 45, and 50 CAT taper sizes, as well as all HSK A and C tapers. One set of sleeves is included with each fixture.

Read More »

Welding Fixture handles prototypes.

With Demmeler modular fixturing system, fixtures for prototypes, specials, spares, or any other short run welding job can be ready in four hours or less. It includes full range of components to fixture virtually any part. Engineering changes are easily handled. Duplicate fixtures can be ready in 20 min.

Read More »

Machining Towers align parts accurately.

SeraLock(TM) Towers have 8 or more clamping stations with serrated mounting surfaces, suitable for small and mid-size horizontal and vertical machining centers. Serrations on mating surfaces are machined so that exact match is created between surfaces, and no special equipment or skill is required to align clamping components. Spacing or pitch of serrations allows use of variety of short stroke...

Read More »Locking Kits fit Haas machining centers.

Ball Lock(TM) fixture kits contain all components needed to locate and lock fixture plates to subplates. System provides quick change capability, and holds plates together with working loads up to 20,000 lbs. Standard kit includes correctly-sized subplate and fixture plate, both pre-drilled with ball lock bushings installed and correct number of shanks, T-slot nuts, sine fixture keys, and socket...

Read More »

Oilfield Improvements® Wheeled Rod Guide® Couplings Celebrate 35th Anniversary

For over 35 years our Wheeled Rod Guide Couplings, have been at work in oil fields across the globe. Our products are engineered to extend the service life of sucker rods and tubing, delivering cutting-edge innovation that enhances oilfield operation, maximizes output, and enhancing overall operations. To learn about the advantages of using Wheeled Rod Guide Couplings in your wells, see our video.

Read More »