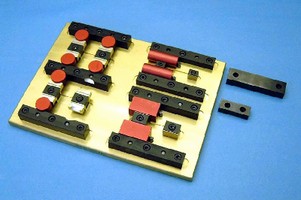

Locating Rails facilitate fixture building.

Available in variety of sizes and lengths, low-carbon, precision ground Locating Rails include mounting holes and socket head cap screws. Users mill slot in fixture plate to locate rail and drill and tap mounting holes. Height of rails can be adjusted by depth of slot. Steps can be machined on rails to hold work piece above fixture plate, or radius can be machined to match contour on machinable...

Read More »

Workholding Blocks enable machining of 5 sides.

Using permanent, rare earth magnets, MagVISE Blocks securely hold workpieces without manual fixturing or vise set-ups. Each is rated to 4,620 lb of holding power, with 3.5X safety factor, for over 16,000 lb of magnetic force. Blocks use no electricity, are maintenance-free, and will never wear out. They can be ganged together to create custom workholding solutions.

Read More »

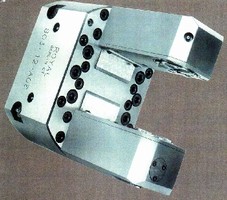

C Frame Fixtures enable complete machining.

Clamping on parts' bodies and not on flanges, C Frame Fixtures enable complete machining of large valve body flanges and weld connections. Units minimize number of operations required in production and can accommodate family of parts through use of interchangeable top clamps and nests.

Read More »Tap Holding System features one-touch axial adjustment.

With STM Tap Holding System, tap projection length can be adjusted by hand rotating guide ring on outside of toolholder. Axial adjustment range varies depending on size of toolholder, but is as high as 0.591 in. Taps are securely held in place by 1-piece steel spring collets, and are further prevented from rotating by interchangeable preset drivers. System accommodates 1,000 psi of coolant...

Read More »

No Pencils Required: From Thinking to Knowing Through Mobility

This ebook provides a detailed guide on how mobility and digital data management systems (DDMS) can increase your company's overall effectiveness and efficiency.

Read More »Collet Holder features air-operated design.

Using standard 5C collets, hardened and ground 1-AC Air Collet Fixture holds up to 1 1/8 in. stock or through-stock up to 1 7/64 in. Step-chuck collets and expanding collets can also be used. With max recommended air pressure of 120 psi, double-acting, piston type air cylinder develops holding power 18 x air line pressure. Featuring 2 lugs for mounting, holder can be mounted horizontally or...

Read More »

Modular Fixture holds irregular shaped parts.

Featuring Vee block design and high-tensile adjustable chain, Dual Modular-Style Fixture is adjustable for holding wide variety of different parts. Unit expands and contracts along X-Y-Z axes to suit largest and smallest parts by rearranging basic location of clamping and locating components. Fixture is suited for steam valve industry, which normally requires irregular shaped valves to be...

Read More »Workholding Towers feature 8 clamping stations.

Constructed of 80,000 psi ductile iron bodies with precision machined steel components, HDL ClusterTowers(TM) are intended for mid-size and larger machining centers. They have quick change jaws and provide repeatable clamping to 0.001 in. Self-adjusting holding block of front or back jaw enables clamping of same or dissimilar sized parts. Clamping stations are 6 in. wide with 4 in. opening. Each...

Read More »

Workholding Towers provide repeatable clamping to 0.001 in.

Suited for mid-size and larger machining centers, HDL ClusterTowers(TM) feature 8 stations, each with 6 in. width, 4 in. openings, and clamping force to 6,316 lb at 70 lb of torque. Quick-change jaws lift off vise module with half-turn of hex key, and reset and self-align with no special tools. Self-adjusting holding block enables clamping of same or dissimilar sized parts, while adjustable...

Read More »

Rotary Grinding Fixture features attached sine plate base.

Sine Punch-Mate No. 1 comes with locking hinge, designed to automatically draw down on gage blocks, eliminating need for locking straps or bars that cause accuracy distortions. Made from hardened tool steel, unit features preload ball and race bearing design, concentricity within .0001 in, and squareness and parallelism within .0002 in. Twenty-four 15-° indexing divisions with 10 sec accuracy...

Read More »System facilitates end-effector tool changes.

Model QC-1200 automatic tool changer accommodates different styles of parts on same assembly machine. Modular design options include Device Net Bus module, self-sealing fluid or pneumatic module, 19 pin I/O module, and 200 A weld power module. Integral latch/unlatch sensor signals coupled condition of tool changer. Unit meets demands of robotic resistance welding and material handling...

Read More »

Come Alive Organics' Premium Organic Agave Provides a Healthier Choice

Come Alive Organics distributes all-natural, proprietary flavored agave for the food and beverage industry while helping children across the globe. Learn more about our agave products and our one sweet cause in this video and two-page PDF.

Read More »