Hydraulic Fixtures maximize capability of HMCs.

Press Release Summary:

Hydraulic Custom Fixtures handle multiple parts per side for first or secondary operation on horizontal machining centers (HMCs). They can handle large and difficult parts resulting in reduction of set-up and production times. Depending on required system, multiple column configurations are available.

Original Press Release:

Royal Custom Designed Hydraulic Fixtures Maximize the Capability of Horizontal Machining Centers

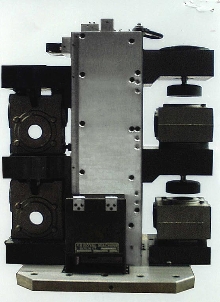

Berlin, CT - New Hydraulic-Fixtures from Royal Workholding have the capacity to handle large and extremely difficult parts resulting in the reduction of set-up and production times...plus increasing the overall capability of horizontal machining centers. In the system illustrated, the fixture holds four (4) large housings for two (2) operations parts with a control

valve for each side for easy loading and unloading.

Designed and built in the USA to custom requirements for use on horizontal machining centers, Royal Machine & Tool Corporation design features provide the means to combine more operations and the reducing of overall handling time. Thus, providing the means for substantially increased productivity.

Royal Hydraulic Custom Fixtures are designed to hold multiple parts per side for first or secondary operation on horizontal machining centers. Depending on the required system, multiple column configurations are available.

Royal Workholding designs and builds custom and standard workholding devices from simple manual fixtures to modular units holding families of parts without dedicated fixtures. In addition, Royal provides custom and standard chucks of all types for rotating and non-rotating applications.