KUKA Robotics to Demonstrate Order Picking by Layer Concept at PackExpo 2006

High Payload Robot Fitted with Specialized End of Arm Tool Allows Manufacturers to Streamline Distribution by Palletizing and De-palletizing Products by Layers Clinton Township, Michigan - September 25, 2006 - KUKA Robotics Corporation, a leading global manufacturer of industrial robots, today announced it will demonstrate its new order picking by layer concept on its booth (#S-830) at PackExpo...

Read More »RPT to Demonstrate Router Trimming, Material Handling and Software Capabilities at 2006 SPE Thermoforming Conference

AUBURN HILLS, Mich., Sept. 6, 2006 - Robotic Production Technology, North America's leading robotic trimming solutions provider, will showcase its new RoboTrim-® RT-500 router trimming system, it's popular RoboTrim(TM) RT-1000 router trimming system and demonstrate it's advanced material handling, AccuFind(TM) part variation sensing and software abilities at the 2006 SPE Thermoforming Conference...

Read More »Robots are suited for laser welding/cutting applications.

Robots, which feature modular design that promotes application flexibility, are intended for laser welding, laser cutting, and measuring applications and can also be reconfigured for use in tasks such as adhesive application. Despite size and reach capabilities, each robot offers path repeatability of 0.1 mm. Models KUKA KR 100 HA, KUKA KR 100 L90 HA, and KUKA KR 100 L80 HA offer respective...

Read More »Six-Axis Robot provides abrasive water jet trimming.

Utilized in abrasive water jet applications, AccuTrim WJ-110 is equipped with Severe Dust and Liquid Protection package that delivers environmental rating of IP67. Robot also includes FANUC R-J3iC controller, Integral Diamond Eductor nozzle, and high-pressure, swivel-free plumbing package. Choice of H2O Jet Ultra High Pressure Pumps is available to produce up to 60,000 psi of water pressure.

Read More »

Wear - What Wears in Electromagnetic Brakes

Learn the common causes of wear for "fail-safe" brakes and how to prevent wear for safe use.

Read More »

Gripper suits internal and external assembly applications.

Designed to fit O-rings not only to shafts, but also in holes, 6-finger Model ORG 85 features integral stroke and triple jaw sets that move independently from one another. O-ring is first released from first 3 fingers, and then released from last 3 fingers in controlled manner. Clamping width of diameter to be fitted ranges from 5-150 mm. Stroke of 2 sets of triple jaws range from 0-21 mm for...

Read More »

Sorting Robot removes cut shapes from cutting machine.

Dynamic Robotic Parts Sorting system is capable of unloading cut parts by job or offloading to pallets, shelves or conveyors, and integrates with existing CNC cutting operations. Unattended material handling is provided and system offers seamless process from sheet, nesting, and shape cutting to part removal. System features multi-axis FANUC robot and controller, application specific grippers,...

Read More »

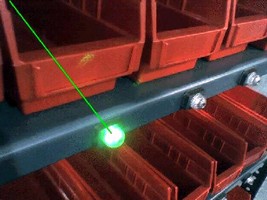

Laser System enables paperless picking.

Laser-Pick(TM) utilizes high-intensity laser beams aimed at reflectors that visibly light up to direct pickers to pick/put locations. Green laser beam can service thousands of pick or put locations and can be utilized where pick-to-light cannot. Because laser beam guides picker, reflectors can be put anywhere without limitations of wiring runs. Supporting wireless, Ethernet, and RS-232...

Read More »

Kuka Robotics Selected by Robotic CNC Solutions to Provide Robots for Large Format Machining Cell

New Machining Cell Utilizes KUKA Robot and Gudel Linear Floor Slide to Give Machinists a Complete and Economical Large Format Machining Product Clinton Township, Michigan - Aug 15, 2006 - KUKA Robotics Corporation, a leading global manufacturer of industrial robots, today announced it has been selected by Robotic CNC Solutions of New Berlin, WI to provide robots for its new large format machining...

Read More »

EFD Solder Paste Group and Leister Technologies Join in Cooperative Worldwide Marketing Effort for Advanced Tabletop Laser Soldering Reflow

Lincoln, RI (August 9, 2006) - The Solder Paste Group of EFD, Inc. and Leister Technologies LLC have agreed to a cooperative marketing effort for a unique, high-speed, high-precision, automated solder paste reflow system designed to substantially increase production yields and deliver greater throughput. Among its many advantages, the times savings alone with the EFD/Leister package could reach...

Read More »

TPA Motion Introduces New Curved Linear Rail Guides: the CR40 Series

For the ultimate in precision open and closed loop guided motion systems, TPA Motion is the leader in curved rail, liner guides. We specialize in engineering excellence, with products that exhibit an elevated level of precision, delivering robust performance, even under the most challenging conditions. See our video to learn more.

Read More »