SCARA Robots automate long reach tasks.

Featuring PC-based control platform, KUKA KR10 series is designed for pick and place, assembly, and material handling applications. These 4-axis robots are available with 600 and 850 mm reaches and are capable of handling payloads up to 10 kg. Link and gear combinations and optimized control loops in kinematic chain contribute to degree of repeatability.

Read More »

DE-STA-CO to Showcase New, Patented Selection of Automation and Workholding Solutions at ATExpo

Madison Heights, Michigan, July 17, 2006 - DE-STA-CO will feature its entire line of products ranging from manual clamps to automation solutions at this year's Assembly Technology Expo (ATExpo) in booth #611. ATExpo will be held at the Donald E. Stephens Convention Center in Chicago, Illinois from September 26 - 28. The newest product to join DE-STA-CO Robohand's impressive list of automation...

Read More »

Robotic Arm suits stretch blow mold applications.

Designed as direct replacement to fit SidelÃ-® Series1 machines requiring fixed head, Series BST Fixed Head Transfer Arm incorporates hardened stainless steel head and jaws for extended service life and reduced maintenance/downtime. Low-profile, 30Ã-

Read More »

Six-Axis Robots handle payloads of up to 5 kg.

Available in 650 and 850 mm reach models, KR5 Sixx family of robots is designed for assembly or material handling applications that require 6-axis functionality for long reach tasks. When combined with company's PC-based control platform, compact robots provide users with pick and place automation solution.

Read More »

Bearing Solutions For Your Robotics and Automation Applications

This ebook provides an in-depth overview into bearing solutions for your robotics and automation applications.

Read More »

SCARA Robots handle long reach tasks.

Four-axis KR5 SCARA Robots, when combined with PC-based control platform, provide high-speed, pick-and-place automation solution. Series includes 350 and 550 mm reach models capable of handling payloads up to 5 kg. Lightweight design optimizes acceleration and maximizes working velocities.

Read More »

Multipurpose Robot utilizes R-J3iC intelligent CNC.

Suited for applications from welding to machine loading, R-2000iB comes in multiple model variations, including 165 kg base model and rack-mount model. Slim arm and wrist assembly enables operation in tight workspaces. Vibration control function, provided via R-J3iC Robot Controller, minimizes robot vibration during motion. Robot Link function controls and coordinates up to 10 robots, preventing...

Read More »

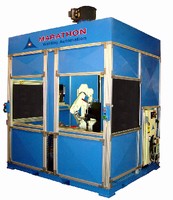

Robotic Cell offers alternative to semi-automatic welding.

Adaptable to all models of robots and welding power supplies, Z-Weld Robotic Cell can be pre-programmed to meet specific material and application needs. With 85 x 105 in. footprint, unit features two 30 x 40 in. tables mounted on common forklift-compatible base that allows portability. It includes manual or automatic doors at load/unload stations, full perimeter guarding with maintenance access...

Read More »Robots suit path-intensive applications.

AccuTrim(TM) models WJ-44/22L/33 and R-44/99/363 include FANUC robot, RPT process tooling, and combination of software features and tools designed for non-metallic product trimming applications requiring tight product feature tolerances and high path repeatability. Robots include quick Tool Center Point Recovery, Collision Guard to protect robot, and robot memory. WJ Series is targeted for...

Read More »Packaging Robot comes with single or double vertical arms.

RaptorÃ-® 3000-HP High Performance Top Entry Robot, suited for injection molding presses rated from 200-800 tons, enables molders to operate 3-plate and stack molds in large presses without dedicated automation equipment. Product features dry cycle take-out time under 0.5 sec and overall cycle time under 5.0 sec with typ payload capacity of 22 lb per vertical arm. Robot is available with...

Read More »KUKA Robotics Installs First Stainless Steel Robot In North America

Clinton Township, Michigan - January 24, 2006 - KUKA Robotics Corporation, a leading global manufacturer of industrial robots, today announced its system partner, Forte Automation Systems, has installed a KUKA KR 15 SL stainless steel robot into Dean Foods' dairy product manufacturing facility. The robot is the first stainless steel robot to be installed in North America. Dean Foods, a division...

Read More »

Triad's Next-Gen Power Supplies Offer Increased Reliability and Reduced Noise Performance

Triad Magnetics, an established leader in power supply design and manufacturing, is proud to announce their next generation WAU AC and WDU DC Series of power supplies. These linear wall plug-ins offer minimum noise performance without sacrificing reliability or life. See our video to learn more.

Read More »