Lucifer Furnaces Ships Batch Oven to Grinding Machine Manufacturer

Lucifer Furnaces, Inc. has delivered a large tempering batch oven to a leading East Coast manufacturer of precision grinding equipment. Key features of this Series 4099 unit include a vertical air flow pattern and wire-on-rod heating elements. A roof mounted stainless steel belt driven fan with a heavy duty motor provides vertical airflow for uniform heat. Coil wound heating elements mounted on...

Read More »

Rehm Thermal Systems Will Showcase Advanced Drying and Firing Processes for Solar Cell Metallization at SNEC

Advanced processes for the drying and firing of solar cell metallization will be center stage at Rehm Thermal Systems' booth at the SNEC International Photovoltaic Power Generation conference and Exhibition in Shanghai May 5-7. Key members of the Rehm team will be on hand at Booth 5021/2 and will explain to visitors ways in which to increase their cell yield and efficiency. Following exhaustive...

Read More »

500-

No. 945 is an electrically-heated 500°F(~260°C) universal oven from Grieve, currently used for various curing tasks at the customer's facility. Workspace dimensions are 54 wide x 36 deep x 36 high. 6.6 KW are installed in Nichrome wire heating elements to heat the load, while a 600 CFM, 1/2-HP recirculating blower provides horizontal front to rear airflow. The unit has 4 insulated walls, an...

Read More »

Conveyor Oven Cures Ceramic Glue in Automotive Parts

Wisconsin Oven designed and manufactured two (2) electrically heated conveyor ovens to cure ceramic glue in filters for diesel truck exhausts. The customer's process consists of gluing together an array of small ceramic bricks that is sent through the first conveyor oven to remove water from the glue. After the array is dried it is cooled down. Several of the small brick arrays are then glued...

Read More »

Avoid Pressure Equipment Failure

This eBook gives a guide on how to prevent pressure equipment failure.

Read More »

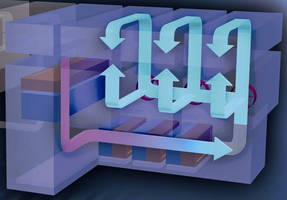

Convection Reflow Ovens employ advanced cooling technology.

Vision Series employs fans in individual zones, available with separate speed/volume control, that can cool lead-free processed PCBAs to below 50Ã-

Read More »Batson Expands Nonwovens Machinery Line

Greenville, SC: In a move to expand their services to the nonwoven industry, Batson Group, Inc., recently announced their newly formed sales relationship with Fleissner, GmbH. Batson through their sales association with American Truetzschler, will now market, in the United States and Canada, Fleissner's spunlace and chemical bonding systems as well as their belt and perforated drum ovens....

Read More »

Belt Conveyor Oven offers 30 x 120 x 15 in. workspace.

Equipped with 18 kW Nichrome wire heating elements, 350-° Model 832 uses 4,100 cfm, 3 hp recirculating blower to provide downward vertical airflow to load. Electrically heated oven has aluminized steel interior/exterior with 4 in. insulated walls. Measuring 24 in. wide, Chemglas 5 x 5 mesh fiberglass fabric conveyor belt is coated with Teflon-® and powered by -¼ hp motor with variable speeds...

Read More »Ovens/Incubators increase laboratory safety, efficiency.

Equipped with ergonomic and intuitive interfaces, IsothermÃ-® Laboratory Ovens and Incubators utilize Solaris(TM) Pre-Heat Chamber Technology for temperature uniformity. Heat is transmitted into the chamber via 4-zone heated air jacket, and VentiFlow(TM) Ventilation System offers adjustable fan speed and air exchange rates to meet application requirements. Also included, SmartSense(TM)...

Read More »

Hot Bonding Machine is used for curing applications.

ACRÃ-® 3 Hot Bonder is available with one or two zones, each featuring 10 thermocouple sensors, 30 A max output, and dual vacuum system (electric pump and vacuum venturi). Operated via 8.4 in. color touchscreen interface, machine offers temperature control up to 1,400Ã-

Read More »

Gas-Fired Walk-in Oven provides temperatures up to 500-

With 48 x 48 x 72 in. workspace, No. 1003 includes modulating natural gas burner with 800,000 BTU/hr and 3 hp recirculating blower providing vertical upward airflow. It features 4 in. thick insulated walls; aluminized steel exterior; Type 304, 2B finish SS interior; and insulated floor with truck wheel guide tracks. Onboard safety equipment processes flammable solvents and unit also includes...

Read More »

Ensure Safety, Reliability in Your Cement Plant with Aerzen Blowers and Compressors

Aerzen offers blowers and compressors for challenging cement applications such as pneumatic conveying from raw mill to raw meal silos, combustion air, cement silos fluidization, and more. At Aerzen, safety is our top priority. Check out our video to learn more.

Read More »