Infrared Conveyor Oven thermoforms medical stints.

Featuring 4 in. x 1 ft 2 in. x 1 in. heating chamber and 1,300Ã-

Read More »

Salt Bath Furnaces suit various heat treating applications.

With maximum operating temperature of 1,800Ã-

Read More »

Infratrol Manufacturing Corp. at Coating 2009 West

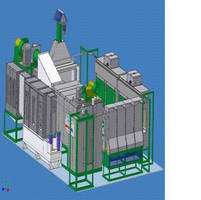

New Berlin, WI Feb., 05, 2009 Infratrol Manufacturing Corp. will be displaying at the Coating 2009 West , March 2 & 3, 2009 at Planet Hollywood in Las Vegas, NV, BOOTH #235. They will be displaying their EcoFlex powder coat system with a single stage, ambient pretreatment system and their MicroFlex powder coat system with a multi-stage water based pretreatment system. Both systems are complete...

Read More »

Convection Reflow Oven uses flux residue management system.

VisionXP employs complete flux residue management system, which combines pyrolysis action mechanisms in preheating and peak zones with cold condensation in cooling zone. Complex molecules are broken down into simpler substances via temperatures from 500 to 900Ã-

Read More »

What You Need to Know About Barrier Technology for Your Food Package

Learn about the Benefits of Barrier Technology

Read More »Conveyor Oven Designed for Hydrogen Embrittlement Relief

Wisconsin Oven designed and manufactured two Electrically Heated Conveyor ovens to perform hydrogen embrittlement relief on locking wheel lugs at a maximum production rate of 1,600 pounds of parts per hour for each oven. Each oven has a 4'2 wide x 31' long x 9 high heating chamber and a 500Ã-

Read More »

Gas-Fired Conveyor Oven preheats tubes for oil industry.

Along with 12 ft x 47 ft x 9 in. chamber rated to 500Ã-ºF max, bottom-flow conveyor oven features chain style conveyor with 10 strands of carbon steel chain spaced across width on 60 in. centers. Heating system features Eclipse 320 AH burner rated at 3,000,000 BTU/hr, and Allen-Bradley Powerflex VFD provides conveyor speed adjustability from 1.5-9 ipm. Oven is constructed with 4 in. thick...

Read More »

650-

No. 894 is a 650°F electric heat belt conveyor oven from Grieve, currently used for sintering Teflon material onto flat sheets at a customer's facility. The workspace dimensions of this unit measure 30 W x 48 D x 15 H. Workloads travel on a 24 wide, 1/2 x 1/2 316 stainless steel conveyor belt, driven by a 1/4 HP motor drive, variable from 0.4 to 8.4 inches per minute. An 18 long open belt...

Read More »

Vitronics Soltec Launches XPM2+ Reflow System; All the Performance 'Plus' Enhanced Features

Stratham, New Hampshire, USA - Customers of Vitronics Soltec's successful XPM2 Reflow System can now get all of the performance and reliability that the system is known for, plus some enhanced features, in the XPM2+. There's a lot that's new, while the exterior of the XPM2+ boasts a better, leaner look, the main enhancements are to its conveyor system; cooling system; electrical control system;...

Read More »

Sunburst EMS Announces Enhanced BGA Rework Capability

July 3, 2007 West Bridgewater, Massachusetts, USA - Sunburst EMS announces the expansion of its SMT and BGA rework and servicing capability with the acquisition of a new A.P.E. 'Intruder' hot gas-based rework system to round out the company's PCB assembly capabilities. According to APE's Technical Director David Horvath, The Intruder system that we have supplied to Sunburst is designed especially...

Read More »

Precision Machining Solutions with Over 25 Years of Experience

Quality, customer service, and unbeatable value are the hallmarks of Hogge Precision. Since 1989 we have built a reputation as the go-to precision machining source, servicing many demanding industries. For CNC machining and screw machining, there are few manufacturers that can match our capabilities and expertise. See our video to learn more.

Read More »