Convection Reflow Ovens employ advanced cooling technology.

Share:

Press Release Summary:

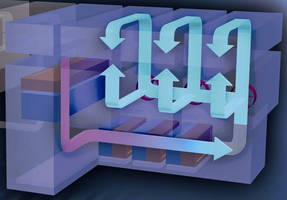

Vision Series employs fans in individual zones, available with separate speed/volume control, that can cool lead-free processed PCBAs to below 50°C. Depending on system length, cooling area in VisionXP is laid out in 2, 3, or 4 stages. System also provides precise cooling gradients critical to reduce thermal stress and resulting board twist/warp. Bottom-side cooling configuration is also available to ensure homogenous cool-down of large thermal mass PCBs.

Original Press Release:

Enhanced Reflow Cooling Technology Introduced by Rehm Thermal Systems

Rehm Thermal Systems has introduced new cooling zone designs for their Vision Series convection reflow ovens. The new technology is particularly effective for the homogenous cooling of large thermal mass PCBs.

Depending upon the length of the system, the cooling area in the VisionXP is laid out in 2, 3 or 4 stages. The fans in the individual zones, which are available with separate speed/volume control, can cool even lead free processed PCBAs to below 50° C. The system also thereby provides precise cooling gradients that are critical to reduce thermal stress and resulting board twist and warp.

A highly effective new bottom side cooling configuration is now also available to assure even more homogenous cool-down. This design is particularly useful for uniformly processing thick PCBs, workpiece carriers, and PCBs with unevenly distributed inner copper layers, all of which present more thermally challenging processing.

Rehm Thermal Systems, celebrating their 20th anniversary this year, continues to develop advanced thermal solutions for the most difficult electronics assembly applications. With thousands of reflow ovens in operation throughout the world, Rehm also remains the only single source for both convection and condensation soldering systems in the world.

"Lead free conversions and complex high thermal mass products stress traditional reflow processes," commented John Bashe, Rehm General Manager. "Rehm has a successful history delivering the kind of advanced thermal solutions necessary to meet such challenges."

About Rehm Thermal Systems

Rehm Thermal Systems (www.rehm-group.com) is an international supplier to the photovoltaic and electronics industries, specializing in curing, drying and firing technologies as well as convection and condensation soldering. Rehm operates vertically integrated manufacturing facilities in Germany, China, and Russia, and technical support facilities throughout Europe, Asia and North America.