Chemical Injection Technologies, Inc. Unveils New Products at WEFTEC

FORT PIERCE, Florida/October 5, 2006- Recognized as a world leader in water and wastewater treatment and an ISO certified company, Chemical Injection Technologies, Inc. (CIT) will be unveiling its newly patented SUPERIOR(TM) VacuFeed, SUPERIOR(TM) Gas Detector, SUPERIOR(TM) High Capacity Gas Chlorinator, and SUPERIOR(TM) Floor Cabinet at the Water Environment Federation's Technical Exhibition and...

Read More »

Prefeeder interfaces with orienter/assembly equipment.

Used for storing and feeding bulk products, OP Series features variable speed drives and gear driven mechanical transfers and is offered with standard capacities from 3-20 cu ft. Incorporating non-vibration design, product is offered in overhead, floor level single belt elevating, and floor level dual belt elevating configurations. Options include SS construction, custom designed cleats for...

Read More »

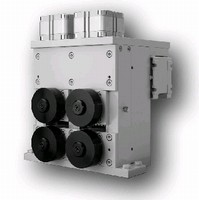

Feeders handle wire, tube, and cable.

Utilizing pneumatic cylinder for max clamping and pulling forces, 2-roll Model NA S and 4-roll Model NAD S are suited for operations that work with wire, tube, and cable in coil making, cutting, forming, and straightening applications. Size of housing does not limit applied force since pneumatic cylinder is positioned on top of housing. Both feeders can handle material with diameters from 0.5-15...

Read More »Friction Feeder handles mail-order insertions.

Accommodating different sizes and thicknesses of materials, Large Capacity In-Feeder 3000 allows large range of items to be fed into boxes or totes along existing conveyor lines. Dual separation technology helps keep belt wear to minimum, enabling months of operation without changing belt. Able to handle up to 4,000 sheets of paper and feed 60 products/min, feeder handles everything from small...

Read More »Expanding Access: How to Get At-Home Medical Tests to Market and Patients

This e-book discusses how to get at-home medical tests to market and patients.

Read More »Weigh Belt Feeders withstand harsh industrial environments.

Providing feed rates up to 3,000 t/hr, Heavy Industry Weigh Belt Feeders feature low deflection, non-wearing Force Measurement Suspension System weight sensing scale. Weight transducer is located outside feeder enclosure to prevent damage and tare build-up. Dead weight of weigh idler and belt is mass-counterbalanced for resolution and signal-to-noise ratio, and machines allow re-rating of feeder...

Read More »

The Multi-Spindle Line Expanded with the BASIC, a Less Sophisticated and Economical Bar Loader System.

The multi-spindle line has been recently expanded with the BASIC, a less sophisticated and economical bar loader system. The Basic maintains the original lathe feed-out mechanism thus replacing the stock reel. During the loading cycle an electrical motor controlled by a PLC pushes the bar stock through the feed fingers. BASIC features a quick loading time and does not require additional floor...

Read More »

Automatic Bar Feeder features single-spindle design.

Used for applications such as running hex bar stock, Series One automatic bar feeder includes hydrodynamic bar guide system and spring bushing device inside lathe spindle. Electrical axis uses 2 encoders in constant communication to synchronize bar pusher with moving headstock. System offers control of feed-out to within 0.2 mm accuracy, and is available in magazine rack configuration for bar...

Read More »

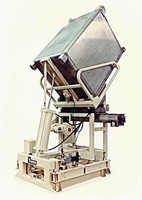

Portable Bin Unloader features loss-in-weight feeding.

Loss-In-Weight Portable Bin Unloaders allow accurate discharging and metering of material stored and transported in side or bottom discharge portable bins. Weighing is done through low deflection, non-wearing Force Measurement Suspension System (FMSS)flexure scale which measures vertical loading and can take high load directed overloads. FMSS scale design uses counterweights to negate tare weight...

Read More »

Miller To Showcase New Plasma Cutter, TIG Welder, Helmet Designs and More at 2006 Fabtech International/AWS Welding Show

APPLETON, Wis., 2006 Miller Electric (booth #23040) will showcase several new products, enhancements to existing products and a new Roadshow semi trailer-- a traveling welding and cutting exhibition, complete with classroom--at the 2006 Fabtech International/AWS Welding Show in Atlanta. New products on display will include the SycrowaveÃ-® 200 AC/DC TIG/Stick welder, the SpectrumÃ-® 1251...

Read More »

Feed Stations store liquids and other chemicals.

Available in 175, 200, and 250 gal capacities, Chemical Feed Stations feature overflow basins and are constructed from high-density crosslink or corrosion-resistant, FDA-compliant, linear polyethylene. Volume markers are designed for optimal visibility, and shelf supports most pumps and metering devices. Along with stackable polyethylene stands, options include fiberglass shelves for pump and...

Read More »

Don't Let Your Money Drain Down the Hole...Drill Steel with Euroboor

As a globally recognized manufacturer of industrial grade portable tools, Euroboor is at the forefront of drilling and cutting technology. Our reputation as an industry leader is built on robust products that fit a wide range of industrial cutting and drilling applications. See our video to learn more about all of our quality products.

Read More »