SCHUNK Products Certified for Use in Cleanrooms

Many SCHUNK products can now be used in cleanrooms without hesitation. This is confirmed by the certificate issued in December 2007 by TUV Sud. The certificate confirms suitability for use in Class 5 cleanrooms according to ISO 14644. ISO Class 5 is comparable to Class 100 of the US-Fed. -Std. 209, which is no longer valid, but still frequently referred to. SCHUNK succeeded in certifying entire...

Read More »

Pneumatic Parallel Grippers handle wide and large parts.

Available in 10 sizes, AGW Parallel Grippers provide 50-150 lb of gripping force and come in 6 strokes of 0.75, 1.00, 2.00, 2.50, 4.00, and 6.00 in. Sealed design repels chips and contaminates from internal mechanism. Each jaw is supported by 2 full shafts through length of body. Featuring rack and pinion design, grippers are offered in synchronous or non-synchronous models with independent jaw...

Read More »

Pneumatic Grippers are suitable for dirty environments.

Parallel Pneumatic Grippers provide rigid gripping of large and wide parts in machining environments. Features include sealed chip-repellant design, rack and pinion grippers, dowel pin holes, and dual full-shaft jaw support. Units are available with Ã-¾, 1, 2, and 6 in. stokes, 4 different bore sizes, and gripping forces ranging from 50-150 lb. Options include synchronous or non-synchronous...

Read More »

Grippers automate seal/O-ring placement assembly.

Able to spread and place up to 12 in. ID seals, AGP-8-OR facilitates part ejection and part seating. Pneumatic parallel gripper offers independent spreading and ejector movements and has 1.5 in. dia through hole. It can be tooled to accommodate all types of rings from .5-12 in. ID, and end of stroke sensing is available. While 8-jaw AGP-8-OR measures 5 in. dia x 5 in. tall, 6-jaw version...

Read More »

Metal Stamping for Construction Tool Applications

Metal stamping is a highly versatile manufacturing technique, capable of producing quality components at tight tolerances.

Read More »

Robotic Gripper targets laboratory applications.

Scalable for use in variety of industries and applications, stepper-based Smart Gripper 2.0 features fail safe brake system, accurate robotic finger positioning, and adjustable grip force without need for software or controllers. Programmable unit can be integrated with most robots and is designed specifically for micro plate handling. Operating using 24 Vdc discrete signals, gripper enables up...

Read More »Two-Finger Parallel Gripper operates in harsh conditions.

Series DPG-plus Sealed 2-finger parallel grippers handle small components in extreme environments. Gripper offers IP67 contaminant protection and operates in rough, dirty, abrasive-dust filled, and underwater environments. Other features include serrated guidance, oval piston wedge-hook base jaw design, hoseless direct air supply, and gripping forces of up to 110 N. Unit can be flexibly attached...

Read More »

Parallel Gripper offers 2,200 N of gripping force.

With total finger stroke of 11.8 in., Model PFH 150 2-finger parallel gripper is designed for handling large and heavy components. It provides finger opening and closing times of 0.8 sec due to end position damping that also ensures quiet return to end position. Air supply can also be connected without hoses, and unit can be attached on 2 sides in 3 screw directions. Product features pneumatic...

Read More »DE-STA-CO to Bring Fresh Perspective to EASTEC 2007 with Horizontal Clamping Series

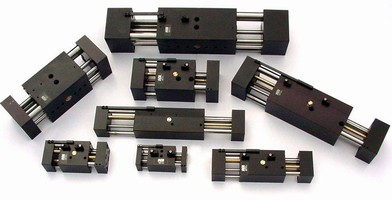

Auburn Hills, Michigan, March 1, 2007 - DE-STA-CO's booth at EASTEC 2007 will feature the Horizontal Handle Hold-Down Action Clamps, the company's latest generation of manual toggle clamps. Also located in booth #5854 will be the DE-STA-COÃ-® Toggle Lock Plus manual clamps, as well as DE-STA-CO Robohand's RZA Table-Top Linear Thruster Slide and DPW Parallel Gripper. EASTEC 2007 Exposition...

Read More »

>SAS< Automation, Introduces New GRF 20 - Long Life Gripper Finger

Xenia, OH (November 2006) - >SAS< Automation is proud to expand options for End-of-Arm Tooling construction by re-engineering its GRF size 20 product line - to make it last even longer. This popular GRF has the capability to cycle significantly more than its original high quality gripper line. The GRF is a pneumatically controlled spring return gripper which is used to secure the more difficult...

Read More »Gripper uses rotating curved needles to secure insert.

Designed for insert mold applications, including cloth or vinyl, GRN advanced and curved needle grippers feature offset locator that promotes insert placement accuracy and repeatability. Rotation of curved needles secures insert, even on thin cloth material. One version is spring-loaded, and 2 versions have gripper arms that fit SAS's clamping system. Integrated cylinders and 2 pressure air ports...

Read More »

Acoustic and Thermal Solutions for Original Equipment Manufacturers

Technicon's products solve the most complex noise pollution and thermal problems and improve product marketability. Check out the video to learn more.

Read More »