Polymer-Based Finishing Solution promotes wear resistance.

Super-Finishing produces low roughness while hardening metal surface using single mechanical process. Mechanical lapping process creates organic layer that bonds into metal surface through chemical reaction, affecting surface roughness average, mean roughness depth, amplitude, and bearing area curve. Environmentally friendly solution does not use hazardous waste materials and can be applied to...

Read More »Bore Finishing System suits heavy equipment bore repair.

Designed to facilitate on-site precision bore repair, BOA-SIZER is used after bore welding and boring to achieve accurate, consistent bore diameter and finish. Product can be used on all types of equipment, in any position, and features adjustable stop system. Along with right- or left-handed operation, system offers onboard weight compensating device for vertical operation. It adapts to BOA...

Read More »Pressure Cup delivers consistent finishing results.

Available in 3 model options to suit non-agitated, rotary agitated, and oscillating agitated applications, 2-quart SG-2 Plus(TM) delivers continuous mixing capabilities. Four-screw lid design facilitates hose attachment, while divorced design of regulator and handle aids in maintenance. Dual-regulation is provided for rotary agitation models, and all models incorporate check valve that prevents...

Read More »Finishing Machine handles cylindrical parts.

Super Finishing Machine, Model HL300 is designed to finish honing and lapping face or inside/outside diameters of small to medium sized cylindrical parts. It sits on heavy steel base measuring 25 x 28 x 36 in. Machine can be used with variety of stones from course to superfine vitrified, CBN or diamond, depending on application. It contains 16-gal coolant system with pump, bag type filter, cycle...

Read More »Are Starrco Modular Systems Right for Your Application?

Prefabricated construction is a type of construction method that involves manufacturing building components off-site or in a controlled environment

Read More »Round-Bowl Finishing Machines offer add-on options.

Vibratory finishing equipment, available in 5 models, are offered as basic units with optional add-on features: automatic separation of parts from finishing media, automatic lubrication of vibratory bearings, and variable speed drive. Long-radius design enables once-around deburring of parts. Suited to batch and individual parts finishing, products offer tub capacities of 5, 9, 16, 25, and 40...

Read More »Surface Finishes do not contain lead or cadmium.

Lead- and Cadmium-Free Electroless Nickel surface finish is electroless nickel process yielding mirror bright nickel phosphorus alloy that offers corrosion resistance, uniformity of coverage, and repair and salvage capabilities. Trivalent Chromate Conversion Coating produces protective coating on pure aluminum, zinc, and anodic aluminum. It minimizes corrosion, provides bonding surface for...

Read More »

Furniture Repair Kit eliminates wood fillers and staining.

Hot Tool FR-Kit includes LK-1 Lacquer Burn-In Knife with spatula-shaped tip that heats up, melts, and smoothes lacquer sticks into cracks and gouges on wood furniture. Measuring 6 in. long, knife has tapered wooden handle that stays cool and 11/16 in. wide tip that heats up to 300Ã-

Read More »

Electric Reciprocator delivers smooth, precise control.

Suited for critical regulation in blended pattern applications, Electric TurboDisk Reciprocator features fail safe breaking and counter balanced drive tube for smooth operation and control over paint film deposit. There is no hydraulic tubing to run and install, and unit does not require oil fill/flush procedure. Configured to deliver stroke lengths from 5-32 ft in 1 ft increments, unit provides...

Read More »

Dust-Free Finishing System is suited for building industry.

Abranet(TM) Deco Sander performs dust-free finishing on walls and ceilings, helping to maintain clean work environment. System is made up of telescopic sanding tool that uses proprietary abrasive material coupled with industrial-type vacuum cleaner. Suction of vacuum can be adjusted to allow unit to stick firmly to ceiling. Material has thousands of holes across surface that facilitate dust...

Read More »

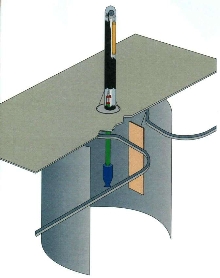

Microfinishing Machine is pneumatically operated.

Single-station Series 140M Centerless Microfinishing Machine features vertically mounted, pneumatically operated microfinishing unit, which includes abrasive film holder, guides, and indexer. It imparts micron-level surface finishes to cylindrical, single- and multi-diameter parts up to 7 in. in length, and between 0.16-1.0 in. diameter. Oscillating tooling applies fine abrasive film to rotating...

Read More »

SEALTITE® Fittings and Cord Grips Offer Longer Lasting Protection

Anamet Electrical's 316 Stainless steel SEALTITE® fittings and UL-listed cord grips protect sensitive wiring components from fluids, corrosive contaminations, bumps, and abrasions with a steel core and liquid tight conduit jacket. Check out this video to learn more.

Read More »