Finishing Machine has 22 ft long radius channel.

Automated, continuous thru-feed Model XLR-22 features round-bowl design for deburring and finishing of metal parts. Cycle/separation options include continuous once-around-and-out processing, or batch cycling for parts requiring longer deburring exposure. Bowl is 8 ft in diameter and lined with 1 in. cast-molded urethane for parts protection. It has 8Ã-¼ in. tub cross-section, full-length tub...

Read More »

Microfinishing Attachment improves surface finish on any material.

Microstar Microfinisher is independently controlled, mounts to any lathe or grinder, and is available in 115 or 250 Vac versions. It uses abrasive film, backed by oscillating platen in contact with workpiece. Abrasive film, available in range of grades and standard 2, 4, and 8 in. widths, is automatically indexed from 150 ft roll and can move in either direction without clutch, gearing, or...

Read More »Cut-Off Machine offers integral end finishing.

Model TCC-25 Rotary Tube Cut-off machine offers integrated double end finishing, which allows square or chamfered ends to be provided on one (or both) ends of tube. It allows operator to select desired cut type (thru cut, cut and pull, or end finished) from control panel. Lengths and quantities are user-selectable, allowing the machine to be programmed for automatic operation.

Read More »

Finishing System polishes 24 in. D by 14 in. W wheels.

CNC 12-axis Finishing Machine features adjustable head angle, variable speed buffing spindles, and closed loop positioning. Adjust-on-the-fly technology continuously adapts to each part being finished, allowing automatic processing of parts with minor variations to same consistency. Reinforced steel, 8-station main index table includes independently adjustable table speed, bi-directional...

Read More »

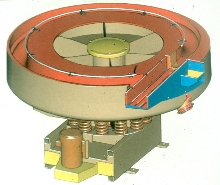

Deburring Machine provides continuous operation.

Model XLR-22 automated, continuous, through-feed machine features round-bowl design and is used for deburring and finishing metal parts. Radius channel is 22 ft long and 8Ã-½ in. wide, assuring constant media mass depth and media action. Time cycles from 4 to 8 min with variable amplitude and vibrations per min offer flexibility. With parts automatically loaded into machine at specific...

Read More »

Crankshaft Finishing System changes over quickly.

Worldflex Microfinishing System achieves circular geometry and surface finish on main and pin journals. Two models handle parts from 10 to 60 in., covering 95% of world's crank sizes. Parts are loaded between headstock and tailstock mounted on slide. Tooling is mounted to end of microfinishing arms, each of which is mounted on its own independent slide. Changeover to process different parts is...

Read More »

Variable-Speed Finishing Systems are custom designed.

Open-face barrel designs provide variable cascading, and are also used where acids might risk explosion in closed barrel. Closed-barrel designs permit full rotation of barrel, parts, and media for aggressive action in longer, unattended cycles. Both styles are available in freestanding or tabletop configurations. Dual-barrel systems are also available. Lined or unlined barrels are available in...

Read More »

Rotor/Brake Lathe operates at one spindle speed and feed rate.

EEBR308A combination rotor and drum brake lathe handles drums or rotors up to 100 lbs using 1 in. arbor. Separate feed motors power twin cutter tool and boring bar independently. Dovetail tool slides with adjustable gibs are protected with felt wipers. Twin cutter tool reconditions both brake rotor surfaces simultaneously and is adjustable with aluminum micrometer dial. Complete packages include...

Read More »

Finishing System produces product in 10 to15 minutes.

BK-TT Mini TRU TEMP(R) part finishing system utilizes black process to provide corrosion protection on castings and powdered metal parts. Two-step chemistry creates black magnetite finish, which is Mil Spec compliant, measures .000020 in. thick, and can withstand 100 to 300 salt spray exposure. Supplied as turnkey system, components include 7 tanks and covers, 2 hot plates, and all chemicals...

Read More »

Finishing Machine offers parts/media separation.

Model OR-5VLR long-radius vibratory unit features 5 cu ft bowl lined with thick molded urethane for parts protection. Separation technology allows for timed discharge of parts, without operator involvement. Variable speed machine has tube diameter of 54 in. and stands 41 1/2 in. high. Automatic lubrication system lubricates 2 vibratory bearings and assures failsafe protection against low air...

Read More »

Standex Engraving Mold-Tech Offers Nickel Shell Capabilities on a Global Scale

Standex Engraving Mold-Tech is the premier, global supplier for mold texturing and surface finishing. With a full range of services, Standex Engraving Mold-Tech is also the only nickel shell supplier producing in three global locations. See our video to learn more.

Read More »