Electric Reciprocator delivers smooth, precise control.

Share:

Press Release Summary:

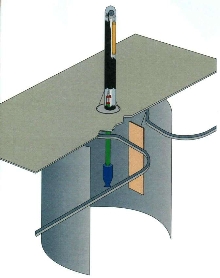

Suited for critical regulation in blended pattern applications, Electric TurboDisk Reciprocator features fail safe breaking and counter balanced drive tube for smooth operation and control over paint film deposit. There is no hydraulic tubing to run and install, and unit does not require oil fill/flush procedure. Configured to deliver stroke lengths from 5-32 ft in 1 ft increments, unit provides for multiple points of hesitation throughout stroke length.

Original Press Release:

Electric TurboDisk Reciprocator for Precision Control

The ITW Ransburg Electric TurboDisk Reciprocator perfect for applications that demand critical regulation in blended pattern applications. The machines smooth operation delivers control over paint film deposit while extending equipment life. The new generation reciprocator is the ideal replacement for existing hydraulic systems.

The reciprocators' advanced features make it lightweight and compact with no hydraulic tubing to run and install. It doesn't require oil fill/flush procedure and eliminates start-up issues due to contaminated control valves. The reciprocator provides reduced costs due to the elimination of the hydraulic power supply reducing operational and maintenance costs.

The new reciprocator can be configured to deliver stroke lengths from five feet to 32 feet. In one foot increments and provides for multiple points of hesitation throughout the stroke length. The new counter balanced drive tube provides energy efficient, smooth operation with enhanced acceleration/deceleration control.

With it's smooth operation and fail safe breaking, the Electric TurboDisk Reciprocator is the answer to all your reciprocator needs.

ITW Ransburg Electrostatic Systems, an Illinois Tool Works Company, offers a variety of finishing products and systems, including electrostatic systems, electrostatic HVLP systems, automatic sprayguns, disks and bells, gun reciprocators, closed-loop fluid control systems, and system parts and accessories. Harold Ransburg first experimented with paint charging and surface grounding technologies in the 1930s, and patented the revolutionary electrostatic finishing process in 1941. Today, ITW Ransburg remains an industry innovator and serves the global liquid electrostatic spray-finishing marketplace from their headquarters in Toledo, Ohio.