Water Deburring Center allows multi-part processing.

Jet-Clean Center 4-axis high-pressure deburring center clears chips and burrs from machined components. Large 20 x 12 x 12 in. XYZ-work area permits large part capacity and/or multi-part processing. Using 5,000 psi water and nozzle technology, unit blasts and dislodges compacted chips and debris from blind, tapped and cross holes and passages. Traveling at sonic velocities to 1,100 ft/sec, water...

Read More »

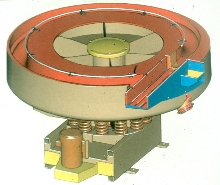

Deburring System is designed for work cell environments.

Requiring 92 ftÃ-² of floor space, Model V-24TF self-contained, vibratory finishing system features built-in material handling equipment and screener that separates parts from finishing media. It has 24 ftÃ-³ capacity, urethane-lined finishing tub and 875-2000 VPM vibration frequency. Sound hoods cover entire length of machine, keeping noise level below 85 dba. Features include...

Read More »

Single Station System offers part deburring and cleaning.

Model EC-20-1 combines Electrolytic Deburring/Edge Finishing/Contouring system and Aqueous Cleaning system. Both are modular and constructed with stainless steel and non-corrosive materials. In combination, systems provide accurate deburred, edge finished or contoured parts that are aqueous-cleaned and dried. Multiple fixtures are provided for load/unload parts handling. Finished parts can be of...

Read More »

Deburring System deburrs short parts in one pass.

BradexÃ-® semi-automatic, double head, flow-through system simultaneously deburrs both ends of short extrusions, measuring from 1-3 in. in length. Each of four 12 or 14 in. disc brushes is driven by 3 hp motor, which are mounted on tool slides for precise alignment of brushes to ends of parts. Variable speed, manually-fed conveyor system allows for deburring rates up to 1,200 parts/hr.

Read More »6 Challenges Faced by Supply Chain Leaders in Discrete Manufacturing and How Analytics Solves Them

This eBook describes the challenges faced by Supply Chain Leaders in Discrete Manufacturing. From consumer electronics to automotive manufacturing, most of the global economy's largest industries rely on discrete manufacturing. Manufacturers in these industries face several unique challenges. The COVID-19 pandemic, followed by war, created major disruptions in supply chains worldwide, stressing the need for more integrated, transparent systems that would facilitate proactive management and faster decision-making. With supply chain issues expected to continue in 2022 and beyond, this ebook will help describe to supply chain leaders ways to prepare for certain global challenges.

Read More »

Thermal System instantly vaporizes burrs and flash.

Large-capacity, 5-station EURO-TEM P-350 Thermal Energy Method system deburrs cast-iron, steel, stainless steel, brass, and aluminum parts, and deflashes zinc parts, completely eliminating burrs and flash internally and externally without parts wear, media or metallurgical change. Parts from 8 in. dia x 7 in. deep to 12.5 in. dia x 12 in. deep are accommodated. While parts are being...

Read More »

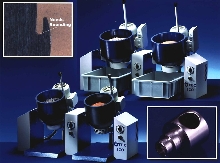

Deburring Machine safely deburrs wide variety of parts.

VORTEX High-Energy deburring machine features adjustable gap system between Tuff Tank and rotating bottom, allowing operator to make adjustments for smaller media and parts so machine can be kept in tight tolerance. It is fully programmable for complete process control. Machine offers inifinite speed control and ability to run variety of media including ceramics, plastic, sintered, natural,...

Read More »

Deburring Center clears chips from critical components.

Jet-Flex 4-axis deburring machine, with 20 x 12 x 12 in. XYZ work area, permits large part capacity and/or simultaneous multi-part processing. Water pressure blasts and dislodges compacted chips and debris. Pumping station is equipped with Triplex Positive Displacement pump, capable of producing water pressure to 5,000 or 10,000 psi. All deburring operations are controlled by G-code programming...

Read More »

Deburring Machine provides continuous operation.

Model XLR-22 automated, continuous, through-feed machine features round-bowl design and is used for deburring and finishing metal parts. Radius channel is 22 ft long and 8Ã-½ in. wide, assuring constant media mass depth and media action. Time cycles from 4 to 8 min with variable amplitude and vibrations per min offer flexibility. With parts automatically loaded into machine at specific...

Read More »

Deburring Machine offers plug and play operation.

ECO benchtop deburring machine offers compact footprint and requires only 115 volt, 60 Hz single phase power input. It is available with 5 liter and 9 liter processing barrels in single or twin configurations. System can be used for dry or wet processing and has optional dosing pump. ECO is suitable for small job shops, cell production within larger manufacturers, and just-in-time processes....

Read More »

Finishing Machine offers parts/media separation.

Model OR-5VLR long-radius vibratory unit features 5 cu ft bowl lined with thick molded urethane for parts protection. Separation technology allows for timed discharge of parts, without operator involvement. Variable speed machine has tube diameter of 54 in. and stands 41 1/2 in. high. Automatic lubrication system lubricates 2 vibratory bearings and assures failsafe protection against low air...

Read More »

560 and 572 Series IP67 Waterproof Inline Plug and Socket Connectors with Shock and Vibration Resistance

EDAC's new line of IP67 waterproof plug and socket connectors represent the cutting edge of waterproof connection technology. Part of the 560 and 572 series of connectors, they utilize innovative design concepts to deliver a level of performance and value that is unmatched in the industry. See our video to learn more.

Read More »