Deburring Machine provides continuous operation.

Press Release Summary:

Model XLR-22 automated, continuous, through-feed machine features round-bowl design and is used for deburring and finishing metal parts. Radius channel is 22 ft long and 8½ in. wide, assuring constant media mass depth and media action. Time cycles from 4 to 8 min with variable amplitude and vibrations per min offer flexibility. With parts automatically loaded into machine at specific metered intervals, XLR-22 is suitable for in-line applications.

Model XLR-22 automated, continuous, through-feed machine features round-bowl design and is used for deburring and finishing metal parts. Radius channel is 22 ft long and 8½ in. wide, assuring constant media mass depth and media action. Time cycles from 4 to 8 min with variable amplitude and vibrations per min offer flexibility. With parts automatically loaded into machine at specific metered intervals, XLR-22 is suitable for in-line applications.Original Press Release:

Innovative Continuous Deburring System from ALMCO Features Long-Radius Channel, Round-Bowl Design

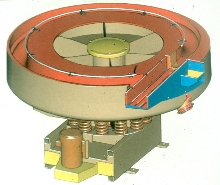

ALBERT LEA, Minnesota (July 1, 2002) - An automated, continuous thru-feed finishing machine that features a new finishing technology in a compact round-bowl design will be featured at the IMTS 2002 exhibit of ALMCO, Inc.

Designed for precision deburring and finishing of metal parts, the labor-saving, energy-efficient Model XLR-22 has a long-radius channel that is 22 feet long and 8-1/2 inches wide. The channel assures constant media mass depth and media action, which are key to strategic processing. Time cycles from 4 to 8 minutes - lower than those an earlier XLR model - with variable amplitude and vibrations per minute offer process flexibility.

The long-radius technology, according to ALMCO, permits once-around-and-out continuous processing, which is especially desirable in work cells. The new technology also offers an additional benefit: the parts tend to stay submerged in the media for a longer time cycle than traditional methods allow.

With parts automatically loaded into the machine at specific metered intervals, the XLR-22 is ideal for in-line applications. Parts can be brought to the unit via conveyor and automatically loaded into the machine.

A variation of the new system offers two time cycle/separation options - either continuous OAAO processing, or batch cycling for parts that require longer deburring exposure prior to automatic media/parts separation.

For further information about the innovative round-bowl system, contact ALMCO, Inc., 507 West Front Street, Albert Lea, Minnesota 56007, phone 1-800-521-2740, or visit the company on the Internet at www.almcoinc.com. The 60-year-old firm is a leading manufacturer and international marketer of metal deburring, finishing, parts cleaning, and liquid filtration equipment and systems that are sold through a network of independent distributors, sales representatives and ALMCO region managers.