Deburring Machine offers plug and play operation.

Press Release Summary:

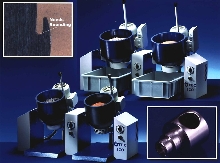

ECO benchtop deburring machine offers compact footprint and requires only 115 volt, 60 Hz single phase power input. It is available with 5 liter and 9 liter processing barrels in single or twin configurations. System can be used for dry or wet processing and has optional dosing pump. ECO is suitable for small job shops, cell production within larger manufacturers, and just-in-time processes. ECOmini is designed for wet or dry, truly small scale use.

ECO benchtop deburring machine offers compact footprint and requires only 115 volt, 60 Hz single phase power input. It is available with 5 liter and 9 liter processing barrels in single or twin configurations. System can be used for dry or wet processing and has optional dosing pump. ECO is suitable for small job shops, cell production within larger manufacturers, and just-in-time processes. ECOmini is designed for wet or dry, truly small scale use.Original Press Release:

Deburring & Polishing In Less Time Saves Dollars

Deburring small engineered, machined and stamped components is now possible in a benchtop format that starts at an amazing price of just $595. The new ECO series of deburring machines from Otec Precision Finish Inc guarantees to reduce the high costs associated with traditional vibro or hand finishing.

Perfect for a small job shop, cell production within larger manufacturers and just-in-time processes, the ECO is sure to increase productivity and profitability. A compact footprint and the need for only a 115 volt 60Hz single phase power input means the device is truly plug and play and can be located near to CNC machines in the cell.

Vice president, Jonathan Dean, explains, "The ECO is so easy to use. It achieves fantastic and repeatable results without supervision, freeing time to work on more productive tasks. Processing is fast - sometimes as little as one minute is all that is required. Being up to 10 times faster than vibro machines and 20 times faster than conventional barrel finishing, means the ECO keeps pace with CNC production and can reduce need for batching. Being small and quite too, means the ECO addresses the space, and health and safety concerns associated with traditional deburring."

ECO is available with five liter and nine liter processing barrels in single or twin configurations. The system can be used for dry or wet processing and has an optional dosing pump. There is even an ECOmini, wet or dry, for truly small scale use.

For the more demanding industrial users who need higher throughput while maintaining exacting standards of finish, Otec recommends the CF range of machines. See the new ECO and CF on the Otec Precision Finish Inc booth B-723 1 at IMTS 2002.

A free consultancy and test processing service for new users is provided by Otec Precision Finish Inc.

More information: Ed Pastore, OTEC Precision Finish Inc. Toll Free: 1-888 511 6832, Tel. 978 635 1964 Fax: 978 635 1478 E-mail: sales@otecusa.com Web: www.otecusa.com

OTEC Precision Finish Inc

20 Main Street

Acton MA 01720