sPINner Small Parts Deburring Machine

The sPINner machine eliminates costly hand-deburring of small, precision parts produced for the medical, electronics, and aerospace industries. It deburrs ferrous, non-ferrous, and hard plastic parts produced on swiss-type screw machines, lathes, machining centers, and plastic injection mold machines. The sPINner uses magnetically activated stainless steel pin media in a soapy deburring solution...

Read More »Machine performs secondary deburring of precision parts.

Using low abrasive media such as sintered ceramic chips, CF-oil system meets demands for smooth surfaces of workpieces subject to mechanical stress in miniaturized assemblies. It is aggressive enough to remove micro-burrs on work pieces without compromising dimensional integrity achieved through final grinding/honing and requires no water connection. Centrifugal disc finishing machine utilizes...

Read More »

EXTRUDE HONE Corporation to Exhibit New Electrolytic Machine at the WESTEC 2006 Exposition and Conference

Irwin, Pa. (March 10, 2006)-EXTRUDE HONEÃ-® Corporation announced today plans to exhibit its new DeskLine(TM) machine, which features its Electrolytic Machining (ECM) process, at the WESTEC 2006 Exposition and Conference in Los Angeles, Calif., from March 27 - 30, 2006. Extrude Hone representatives will be available at booth #2412 to discuss this latest addition to the company's innovative...

Read More »Mounted Points Kit lets user match abrasive application.

Packaged in plastic storage box, Mounted Point Combi Kit includes resin bonded cotton fiber mounted points for deburring, latex bonded cotton fiber units for light deburring and polishing, and soft unitized synthetic fiber mounted points for high polishing. Each cotton fiber or unitized mounted point is impregnated with aluminum oxide or silicon carbide abrasive, which is bonded and compressed...

Read More »

Setting Yourself Up for Sales Success

This ebook provides tips on creating and implementing best practice front-end sales processes.

Read More »

Connectors and Prep Tools facilitate cable installation.

Designed for use with LMR-240 low loss cable, ST-240EZ tool prepares cable to exact dimensions in one step, while DBT-02 tool removes burrs from exposed center conductor. EZ non-solder connectors, which include QMA male, QMA male RA, SMA male, SMA male RA, and N male types, are supplied with adhesive-lined ATUM boot. Optimized to facilitate termination, all connectors are suited for use in True...

Read More »CNC Machine suits rotary deburr or grinding applications.

Developed for plier grinding applications, CNC Rotary Deburr/Grinding Machine consolidates 3 stations on single dial. Hand operations or single station rotary belt grinding operations can also be performed. Standard features include belt speed of 4,000-7,500 fpm, self-contained coolant system with filtration and magnetic separator, speed modification capabilities at each station, real-time head...

Read More »

Duburring Tools suit robotic and CNC applications.

Flexdeburr radially-compliant tools have floating air-turbine motor and spindle arrangement that provides deburring tip's radial compliance to perform consistently on irregular part patterns. Pneumatically controlled tools allow cutting bit to follow part profile, maintaining constant force on part surface. Pivot bearing provides radial movement. Tool requires clean, dry, non-lubricated air for...

Read More »

Water Deburring Center allows multi-part processing.

Jet-Clean Center 4-axis high-pressure deburring center clears chips and burrs from machined components. Large 20 x 12 x 12 in. XYZ-work area permits large part capacity and/or multi-part processing. Using 5,000 psi water and nozzle technology, unit blasts and dislodges compacted chips and debris from blind, tapped and cross holes and passages. Traveling at sonic velocities to 1,100 ft/sec, water...

Read More »

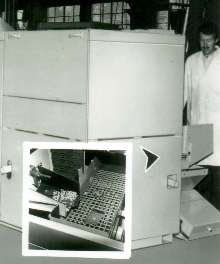

Deburring System is designed for work cell environments.

Requiring 92 ftÃ-² of floor space, Model V-24TF self-contained, vibratory finishing system features built-in material handling equipment and screener that separates parts from finishing media. It has 24 ftÃ-³ capacity, urethane-lined finishing tub and 875-2000 VPM vibration frequency. Sound hoods cover entire length of machine, keeping noise level below 85 dba. Features include...

Read More »

Single Station System offers part deburring and cleaning.

Model EC-20-1 combines Electrolytic Deburring/Edge Finishing/Contouring system and Aqueous Cleaning system. Both are modular and constructed with stainless steel and non-corrosive materials. In combination, systems provide accurate deburred, edge finished or contoured parts that are aqueous-cleaned and dried. Multiple fixtures are provided for load/unload parts handling. Finished parts can be of...

Read More »

New Davenport Hybrid Machine Offers Unique Flexibility for Parts Manufacturing

The Davenport Hybrid machine offers greater flexibility, easier set-ups, and faster cycle times. Check out the video to learn more.

Read More »