Deburring System features return-to-operator configuration.

Suited for applications requiring small footprint and portability, Tri-Ten series planetary head deburring system is designed to deburr both sides of part in single pass. Magnetic conveyor passes parts loaded at one end of system through offset planetary deburring head, where three fiber abrasive brushes deburr upward facing surface, after which part is carried to flipping mechanism and...

Read More »Kennametal Extrude Hone Redesigned TEM S250 Machine

New Machine Design Showcases Technical Innovations and Promotes Greater Levels of Customization while Remaining Budget Friendly Irwin, Pa. (January 09, 2009)-In these uncertain economic times, Kennametal Extrude Hone offers customers interested in its distinctive Thermal Energy Method (TEM) technology the greatest value and production flexibility for the price point with the newly enhanced TEM...

Read More »

Deburring Station minimizes potentially flammability.

Wet Deburring Station uses wet filtration system to capture potentially combustible filings and dust in air/water mixing zone. By entrapping these particles in water, possible flammability is reduced. After pulling filings and dust through air/water mixing zone, material is disposed of as slurry. Model 64100 (21 x 20 x 36 in.) and Model 64100 (36 x 31 x 45 in.) feature tabletop design and can be...

Read More »

Deburring Machine performs 4 functions in one process.

Suited for small to medium-sized workpieces that may be inherently delicate or intricate, CoolPulse 200(TM) electrolytic machine deburrs, polishes, stress relieves, and cleans in one finishing process. Machine can remove rough surfaces from 2.5-5 Ã-µm Ra and produce smooth surfaces down to 0.1 Ã-µm Ra, providing bright or mirror-like finish on stainless steel and bright to matte finish on...

Read More »

Bearing Solutions For Recreational Applications

This white paper provides and overview of bearing solutions for recreational applications.

Read More »

Grinding Machine accepts variety of contact arms.

Equipped with 1 hp variable speed motor, Stationary Versatility Grinder utilizes Ã-¼ x 2 in. wide x 72 in. long abrasive belt that can travel in either forward or reverse motion. Pivot mount assembly allows operator to adjust sanding belt to any angle for optimum comfort, while 4 in. diameter vacuum port enables connection of dust collection systems. Full range of contacts arms is available...

Read More »Cogsdill Will Exhibit Hole-Finishing Tools at IMTS 2006

CAMDEN, SOUTH CAROLINA (April 18, 2006)Cogsdill Tool Products, Inc. will exhibit their complete line of hole-finishing tools at IMTS 2006 in booth #E-2013. Products on display will include burnishing tools and machines; mechanical hole-deburring tools; Shefcut precision reaming and boring tools; brazed diamond reaming and boring tools; automatic recessing tools, generating heads, and precision...

Read More »

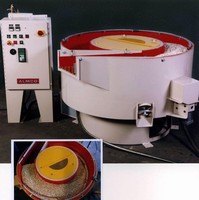

Deburring/Finishing Machine features spiral design.

Model SBB-12 spiral bottom round bowl unit includes full-circle baffle that keeps parts constantly in media mass. Spiral design of up-hill tub bottom enables automatic separation of parts from abrasive media at pre-determined intervals, and allows different parts to move over separating dam to screening area without jamming or hitting. Device features 12 cu ft urethane-lined tub, 7.5 hp drive, 13...

Read More »

Kadia Production Deburring Systems

IMTS-2000 BOOTH #B-6864--Kadia's Production Deburring systems will be presented, showing actual installations. Kadia's unique concepts blend robotics with their own time proven production units to provide high thru-put as well as providing flexibility that is highly desired in today's manufacturing environment. The design of the systems as well as Kadia's proprietary diamond tooling provides...

Read More »

Harig Acquires the Simco Bur-Beaver

June 1, 2006--Harig Manufacturing Corporation announces the acquisition of the Simco machine tool line including the BUR-BEAVER deburring, chamfering, and beveling machines, the Cylinder Mag, Micro-Grind, and Tri-Vise. Previously manufactured by Simco Industries in Roseville, MI, these new items will complement Harig's current offering of world class tools. Harig will reintroduce the most popular...

Read More »

Deburring Machine handles parts up to 800 mm diameter.

Suitable for incorporation into robot cells, bench-top Model 68 2006 deburs gear wheels and contoured profiles on round and oval workpieces such as rings, hubs, and discs. It can be supplied with several spindles running at 2 different speeds. Cutting pressure is adjustable from 10-300 g, and initial tool contact is dampened via adjustable shock absorber. Pivoting suspension device on spindle...

Read More »

Material Handling Solutions from Global Leader in Rubber & Urethane Power Transmission

Megadyne's QST polyurethane timing belts take up less space and guarantee a lower noise level than chain and other traditional material handling belts. Check out our video to learn more.

Read More »