Aprima Medical Software, Inc

Carrollton, TX 75006

Share:

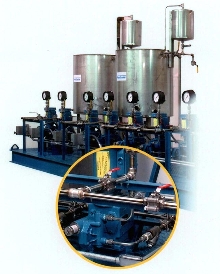

Chemical Feed Systems are custom built for CPI applications.

Built with metering pumps, tanks, portable mixers, and control panels, feed systems are fully piped, wired and tested. Piping is available in all materials, threaded or welded. Systems are packaged with tanks on board and include space for semi-bulk containers or totes. Users also have option to use external bulk containers or totes. Feed systems can be configured for feed rates from 0.02 through...

Read More »

Universal Grinder provides precise grinding of small lots.

GE4-100 Select features solid box-type construction, and ribbed cast bed for rigidity and thermal stability. Wheelhead rotates from 90Ã-

Read More »

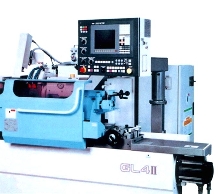

Cylindrical Grinder is programmable for variety of parts.

Model GL4 has box-type, ribbed foundation for rigidity and thermal stability. Hydrostatic/hydrodynamic STATÃ-® bearing technology, in wheel head, eliminates metal-to-metal contact. Grinding-specific control comes with pre-programmed cycles for plunge and traverse grinding. Floating plate mechanism supports both X and Z-axis ballscrews, and prevents transfer of run-out to table or wheel head...

Read More »

Horizontal Machining Center offers 5-axis machining.

Model FA630, with 40 hp, direct-drive, 50-taper spindle, provides infinitely variable speeds between 15 and 6000 rpm. It is also offered with 5000 rpm geared headstock for high-torque, low-speed applications. Boxway design allows FA630 to reach cutting and positioning speeds of 1417 ipm. Pressurized lubrication system rests loaded pallets on micro-thin 0.00012 in. film of lubricant. Spindle...

Read More »

Horizontal Machining Center includes vertical pallet pool.

FA630 features 3-level, 15-station vertical pallet pool, which stocks enough work to support unmanned shift, enabling round-the-clock operation. It has boxway design with maximum rigidity for heavy-cutting applications. Pressurized lubrication system provides positioning and cutting speeds of 1417 ipm. Tools up to 33 lbs are exchanged in less than 2 seconds, with heaviest 60 lb tools taking just...

Read More »

Controller Software increases machine utilization.

WindowsÃ-®-based Cell Controller Software, Level II centralizes scheduling and production management for multiple machines at one shop floor PC. It maintains constant, real-time communication to all machines in cell. All data shown on machine's Fanuc control screen is accessed from PC, allowing remote program changes or modifications. Users can click on any machine icon to check job...

Read More »

Machining Center includes 204-tool magazine and software.

Model FA550 horizontal machining center, with stationary tool storage rack, accommodates up to 340 tools. Magazine handles tools up to 8.5 in. and 80 lbs. Tool gripper, driven by servo motor, travels at 80 ipm. OP Supporter software provides overview of tool magazine and confirms that right sub-programs and tools are ready for each job. Tool change speed is automatically adjusted according to...

Read More »

Cutting Mill grinds biological samples.

Model SM 100 grinder processes organic compound, metal, and textile samples, up to 60 x 80 mm, into fineness of less than 1 mm. Batch size ranges from 5 to 30 liters. Various screens and hoppers allow for adaptation to individual applications. Samples suitable for processing include: bones, cellulose, tissue, compost, silage, corn, cereals, grain, hay, alfalfa, sugar beets, tobacco, roots, wood,...

Read More »

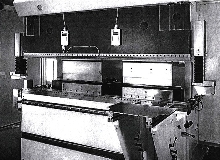

Laser System ensures press-brake operator safety.

BendGuardÃ-® enables foot operation of machine at high speeds, which allows operation personnel to have both hands free for part handling. It is capable of machining any part geometry, regardless of opto-electronic protection. It utilizes 3 parallel laser beams located below upper tool, ~0.35 in. below punch bottom. Laser beams function as hand and finger guards. Effective laser band width...

Read More »Data Logger includes 5 in. probe.

NIST-traceable Model HT125, with waterproof stainless steel case, monitors and withstands temperatures from -40 to +257Ã-

Read More »