Orders for OMAX's Model 55100 Reach 1,000

Company achieves unprecedented growth Kent, Washington - OMAX Corporation, the pioneer of high-quality, precision waterjet machining systems, has recently announced the sale and delivery of its thousandth machine, a Model 55100 JetMachiningÃ-® Center. The accomplishments of the 55100 far exceed the capabilities required for waterjet machining by demonstrating superior precision, cutting...

Read More »Waterjet Cutting Systems produce precision parts.

Featuring HyperPressure Technology, IFB waterjet machine incorporates 87,000 psi waterjet cutting to optimize cutting speeds and jet efficiency while minimizing abrasive consumption and part taper. MicroJet Waterjet Cutting System, built to perform precision machining, complements EDM operations and can cut and drill holes with same machine. Small envelope waterjet system cuts with kerf width of...

Read More »

OMAX-® to Showcase New Solutions for Abrasive Waterjet Machining at IMTS 2006

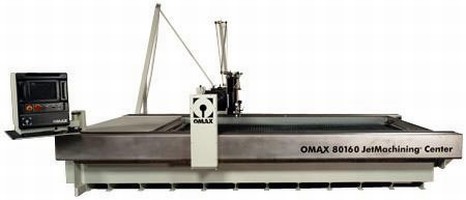

Company's precision waterjet machining centers offer unmatched speed, accuracy and versatility Kent, Washington, June 21, 2006 - OMAXÃ-® Corporation, the pioneer of high-quality, precision waterjet machining systems, will feature two of its premiere JetMachiningÃ-® Centers, the 2626|xp and the 80160, at IMTS 2006. OMAX's innovative machines will be displayed in booth B-6235 in the...

Read More »Waterjet Cutting Systems cut nearly any material.

Powered by 60,000 psi hydraulic intensifier pump, Waterjet Cutting Systems can hold accuracy of 0.005 in. with repeatability of 0.001 in. over entire work envelope. Fully networkable AquaVision DiÃ-® motion controller includes hand-held pendant that allows feed rate override, return-to-path, program zero set points, and XYZ axis control. Digital Readout for Multi Head Positioning digitally...

Read More »

How to Reduce Costs for Plastic Caps, Closures and Other Packaging Products

Check out this white paper to read about the six questions to consider before selecting an injection molder for your packaging application.

Read More »Waterjet Cutting Tables feature jogging pendant.

Offering programmable Z-axis, WaterjetPRO(TM) waterjet cutting tables are made possible by Powered by Flow(TM) program, which enables machine tool providers to integrate ultra high-pressure pump technology. Target markets include small job shops, sign shops, research and development areas within manufacturing operations, and stone, tile, and decorative glass companies.

Read More »

Waterjet adds multitasking abilities to existing machinery.

M-Series enables companies to adapt existing machinery into multi-tasking system by adding waterjet cutting capability. Tent, designed and built to contain all abrasive and water inside tank, makes it possible to keep all M-Series waterjets compact and self-contained. Self-flushing system removes water, abrasive, and any kerf material from inside tank for disposal. Tanks come with 3.5, 5, or 8...

Read More »Maching Service offers water jet cutting option.

Waterjet Cutting platform is available for wide variety of materials including steel, stainless steel, aluminum, brass, bronze, plastics, rubber and exotic metals. Clean, single cutting process often eliminates secondary operations. HammerHead WaterJet uses 60,000 psi stream of water and abrasive grit to cut, shape, drill and finish any 2D design in sheet material up to 4 in. thick.

Read More »

Water Jet Cutting System handles variety of materials.

Hydro-Jet Eco 1005 provides burr-free cuts with no dust, smoke, or fumes. Pure water model is suited for cutting rubber, plastic, foam, and paper materials, while abrasive model excels at cutting aluminum, steel, marble, and compound materials. Both are programmed via integrated PC control with graphic interface. Featuring 20 x 40 in. work area, Eco 1005 offers positioning accuracy of 0.004 in....

Read More »Water-Jet Cutter offers 5-axis cutting capability.

Hydro-Jet System produces 3-dimensional shapes in single-pass operations. It operates with pure water or abrasive-added cutter heads, and includes computer-controlled gantry that guides cutter precisely over workpieces. Modular, stainless steel system features regulated water reservoir and 4-chamber settling tank with connector for abrasive sludge removal system. Materials ranging from thin films...

Read More »

Waterjet Cutting System produces burr-free edges.

Available with optional shuttle table and material handling system, Byjet abrasive, cold cutting system machines variety of flat sheet, tubular, and profiled materials without heat-induced structural changes. AC direct drives provide positioning accuracy at high acceleration rates, enabling machining of intricately shaped parts and contours. HPT High-Precision Tool cutting head delivers precision...

Read More »

Precision Machining Solutions with Over 25 Years of Experience

Quality, customer service, and unbeatable value are the hallmarks of Hogge Precision. Since 1989 we have built a reputation as the go-to precision machining source, servicing many demanding industries. For CNC machining and screw machining, there are few manufacturers that can match our capabilities and expertise. See our video to learn more.

Read More »