OMAX-® to Showcase Full Range of Waterjets at FABTECH 2019

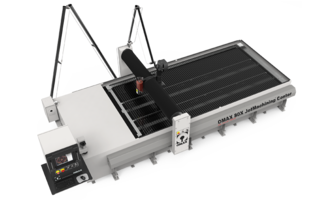

KENT, Wash., July 24, 2019 – At FABTECH 2019, OMAX® Corporation will demonstrate the power of abrasive waterjets on four different machine models. Show attendees can explore each of the OMAX product lines to find out which waterjet is right for their particular applications. In booth A5731 at McCormick Place, Chicago, November 11-14, OMAX will showcase an OMAX 80X with a Tilt-A-Jet, a MAXIEM...

Read More »OMAX to Tout Engineering Benefits of Abrasive Waterjet Technology at IMTS

KENT, Wash.Ã- – OMAX Corporation will highlight how the company’s abrasive waterjet technology is engineered to provide successful cutting solutions to the manufacturing industry at IMTS 2016. OMAX will have live cutting demonstrations in booth N-6228 to showcase how quickly their JetMachining Centers produce high precision parts from virtually any material. Visitors can watch 3D and...

Read More »

OMAX-® Corporation Spotlights Speed, Accuracy of Waterjet Technology at AOG

Attendees to experience highly versatile MAXIEMÃ-® 1530 JetMachiningÃ-® Center KENT, Wash. – For the first time at the Australasian Oil and Gas Exhibition and Conference (AOG) on March 11-13, 2015 in Perth, OMAX Corporation will showcase the many benefits of advanced abrasive waterjet technology. The company and its exclusive Australian distributor, Headland Machinery will demonstrate...

Read More »

Waterjet Machining Centers foster large-scale production.

MAXIEM 2060, 2080, and 3060 JetMachiningÃ-® Centers meet large-scale production needs of shops, OEMs,Ã- and fabricators. While 2060 and 2080 models are suited for large format machining of parts up toÃ- 6 ftÃ- 7 in.Ã- wideÃ- x 20' 6 in. and 27 ftÃ- 2 in.Ã- long, respectively, 3060Ã- model featuresÃ- 10 ft 2 in. Y cutting travel and 20 ft 6 in. X cutting...

Read More »Adhesive Tapes for Energy & Utility Applications

Read about the various types of tapes used in energy and utility applications.

Read More »Waterjet Cutters have hydraulic lifting arm attachment.

Optima L waterjet cutting machines, designed for stone and glass industries, incorporate hydraulic lifting arm attachment for loading/unloading heavy or delicate sheet materials such as granite and glass. Lifting arm attachment accelerates production while also reducing potential of accidental damage to material. Along with rigid construction, features include separate waterjet tank and ball...

Read More »

Waterjet Systems combine capacity and efficiency.

With rigid and sturdy tank design, ballscrew drives, and cantilever-style arm, Emerald 0606 can handle 2 in. sheet of foam or 12 in. thick stainless steel without increased stress. Cutting envelope is 2 x 2 ft, and there is 12 in. of Z-travel. Emerald 0612, offering similar features, has cutting envelope of 2 x 4 ft and can index sheets of unlimited length from front to back. Cantilever-style arm...

Read More »

Jet Edge Introducing Waterjet Cutting Systems for Farm Machine Shops at Triumph of Agriculture Exposition March 12-13

FARM-JETÃ-® and TACH-JETÃ-® Waterjets Cut Parts from Virtually Any Material ST. MICHAEL, Minnesota, U.S.A. — Jet Edge, Inc., a leading manufacturer of ultra-high pressure waterjet cutting technology will introduce its new FARM-JETÃ-® and TACH-JETÃ-® waterjet systems at the Triumph of Agriculture Exposition, March 12-13 at Omaha's CenturyLink Center.Ã- Look for Jet Edge in...

Read More »Maclan Corporation Increases CNC Capabilities

Lakeland, FL - Maclan Corporation, a longtime leader in the polyurethane and rubber products industry, has made major investments in new machinery that allow them to meet the increased demand for their products, which range from roller coaster wheels to rubber linings and dredge hoses. We have dramatically increased CNC turning capabilities, said Maclan spokesperson Maegan Wallace.Ã- With...

Read More »

Michael Waltrip Racing, Jet Edge Renew Technical Partnership

MWR Installing Second Jet Edge Water Jet Cutting System, Brian Vickers Driving #55 Jet Edge Toyota Camry in Virginia 500 ST. MICHAEL, Minn. and CORNELIUS, N.C. – Michael Waltrip Racing (MWR) and Jet Edge, Inc. announced today that they are renewing their longstanding technical partnership.Ã- MWR and Jet Edge also announced that MWR is installing a second Jet Edge water jet cutting system...

Read More »

Waterjet Manufacturer Jet Edge Cuts Logo for National Geographic Channel's 'DIGGERS'

ST. MICHAEL, Minn. - National Geographic TV's new show DIGGERS features a metal DIGGERS logo cut by waterjet manufacturer Jet Edge, Inc. The waterjet-cut logo is featured prominently at the beginning of each episode. DIGGERS, which piloted with two episodes on Feb. 28, features the zany treasure hunting adventures of Tim Saylor and George Wyant, extreme metal detecting experts and founders of...

Read More »

5 and 13 Micron Resolve Columns with Greater Bed Stability

Jordi Labs provides materials solutions that set the standard for innovation and quality. Our line of GPC and GFC columns are on the cutting edge of precision manufacturing and a result of our uncompromising commitment to quality and customer service. See our video to learn more.

Read More »