Case Unloader handles size variations.

Press Release Summary:

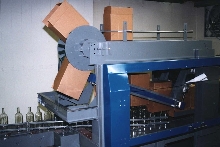

Model 49 decaser automatically unloads glass or plastic bottles and containers from necks-down reshipper cases. It single files containers and uprights emptied cases. Cases are conveyed to packer at speeds up to 75 cases per min. Roller system uses automatic tensioner combined with soft compression rollers. Case turnover offers finger-style grippers that bend to hold cases securely during 180° transfer to overhead discharge conveyor.

Original Press Release:

A-B-C's New Model 49 Case Unloader is Designed to Accommodate Variations in Case Specifications

Tarpon Springs, FL - Case size variations are no problem for the Model 49 decaser, which automatically unloads glass or plastic bottles and containers from necks-down reshipper cases, single files the containers and uprights the emptied cases to be conveyed to the case packer at speeds to 75 cases per minute. The new "soft roller" system that transfers cases through unloading utilizes an automatic tensioner combined with soft compression rollers to accommodate varying case dimensions and ensure smooth and gentle case transfer. The case turnover offers finger-style grippers that bend to hold cases securely during 180 degree transfer to the overhead discharge conveyor. The fingers "bend" to grip the cases, easily adjusting to cases that are slightly smaller or larger than spec. These features are standard on the new Model 49 case unloader, and available as a conversion kit for earlier A-B-C unloader models.

A-B-C manufactures a complete line of packaging machinery including erectors, sealers, packers, palletizers and bulk bottle handling systems for a wide range of applications. For complete details, contact A-B-C Packaging Machine Corporation, 811 Live Oak Street, Tarpon Springs, FL 34689, Phone 800-237-5975, Fax 727-938-1239, www.abcpackaging.com.