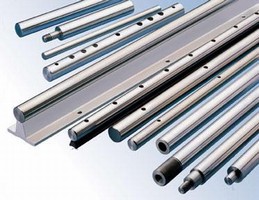

Misumi Announces Greatly Expanded Line of Precision Linear Shaft Designs

Newly expanded product line provides machine builders and factory automation system designers with an exceptionally wide array of linear shaft design options March 10, 2009 (Schaumburg, IL) Misumi USA, Inc., a subsidiary of Misumi Corporation, part of Misumi Group, Inc. (TOYKO: 9962) announces that it has significantly expanded its line of Precision Linear Shafts, components frequently utilized...

Read More »

Energy Efficient Balancer Shaft Leads to Fuel Savings on Mercedes-Benz Engine

14th January 2009 The Schaeffler Group has now commenced volume production of its INA lightweight balancer shaft for the new Mercedes-Benz OM 651 high performance diesel engine, leading to a valuable reduction in fuel consumption. The Schaeffler Group has now started volume production of its INA lightweight balancer shaft and rolling bearing assembly for the new Mercedes-Benz OM 651, a 2.2 litre,...

Read More »

Miniature Spline Shafts do not require external lubrication.

Featuring .125 in. OD, SS 2 Spline Shaft series is designed for light- to moderate-load applications where low friction and extended life are critical considerations. Assembly consists of solid steel or aluminum spline shaft, treated with low-friction Kerkote-® TFE coating, coupled with plain or thread-mount bushings. To adapt to any required format, custom machining of bushing and spline shaft...

Read More »

Differential Shaft optimizes winding operation.

Featuring optimized core grip, GlideLock(TM) clutched rollers on Air-Roll-Lock Differential Shaft slide easily on and off shaft. When disengaged, rollers move freely, allowing operators to move cores and rolls. Once engaged, rollers lock independently in place and are able to control tensions from under .24 pli on each individual core, regardless of core's width.

Read More »

Why Use A Locking Cord?

Learn about the benefits of using locking cords in applications that rely on extensive technological infrastructures.

Read More »

Need it Fast? Thomson 60 Case(TM) Shafting Now Available with Same Day Shipping from Local Stock

WOOD DALE, IL - Genuine Thomson 60 Case(TM) Shafting is now available from stock with same day shipping. The program's current product offering includes 3 in. maximum diameter shafting with cut-to-length and full length shafting. 60 Case Shafting is available in stainless or carbon steel, with standard machining including axial and radial holes and radial flats, as well as custom coatings such as...

Read More »

Students at the University of Buffalo Rely on Products from Igus to Make Their Hiding-Apparatus Project a Success

EAST PROVIDENCE, R.I. - March 29, 2007 - Igus-® Inc., the leading developer of iglide-® plastic bearings, DryLin-® linear bearings and Energy Chain Systems-®, today announced that students studying architecture at the University of Buffalo used donated igubal-® spherical bearings and DryLin S aluminum shafting on a unique project. The team of fifteen, which was challenged to design and build...

Read More »

Kerk's Lead Screws Provide Superior Performance with Kerkote-® TFE Coating

Kerk Motion Products, one of the world's premier manufacturers of non-ball lead screws, offers superior performance lead screw, linear rail, spline shaft and ScrewRailÃ-® actuator assemblies with its KerkoteÃ-® TFE coating. Kerkote reduces friction and extends the life of Kerk's cost-effective, maintenance-free assemblies, which are ideal for motion control applications in a variety of...

Read More »

Shaft is suitable for differential winding applications.

Enabling converters to run multiple width cores on same shaft, Roll Lock Differential Shaft uses GlideLock(TM) Clutched Rollers to control web tension applied to sensitive materials regardless of core width or positioning. Eliminating need for hammers and spacers, rollers move freely and feature external roller bearings to aid lateral core motion during loading/unloading. When shaft is actuated,...

Read More »Shaft Reducers/Extenders have Fairloc hub fastening system.

Comprised of 48 models, S52FCY Series is manufactured in inch and metric sizes to extend shafts to same or different diameters. Hub end of coupling features FairlocÃ-® integral hub fastening system, which eliminates marred shafts. Made of 303 stainless steel, extenders offer zero backlash and are readily adjustable on shaft. They are designed to fit shafts from .120-.500 in. (3-12 mm) dia on...

Read More »Differential Shafts rewind low-tension material rolls.

With tension control as low as 0.1 PLI, Equalizer - D4 allows converters to run ultra-thin films. Its 2-row, 12-ball, torque-activated, core-lock design ensures equalized tension across any combination of roll widths. Equalizer - D2 is suited for repeated slit-width runs with operator-positioned, toolless core stops that can be set and retained through multiple runs, while Equalizer - D3 is...

Read More »

The Carbontec System: A Smarter Way to Heat Your Buildings

Carbontec's paper-thin radiant heating systems reduce energy consumption costs by warming the building surfaces instead of controlling air temperature. Check out our video to learn more.

Read More »