Non-Ball Lead Screws provide quiet operation.

For vertical operation, Non-Ball Lead Screws can be designed to self-lock and prevent back driving, without external brake. They utilize sliding friction between nut and screw to convert rotary input motion to linear output motion. Screws do not need to be hardened, and coating eliminates need for external lubrication. Made from 303 stainless steel, screws range from 1/8 to 15/16 in. diameter,...

Read More »

Roller Screws handle high loads.

SKFÃ-® roller screws, for linear-actuation applications, sustain static loads up to 1,000 tons and dynamic loads up to 200 tons. Planetary roller screws feature threaded nuts, rollers, and screw shafts. Planetary motion eliminates need to recirculate rolling elements, meaning fewer components, smoother operation, and longer life. Recirculating roller screws allow for fine-lead threads, as...

Read More »

Lead Screw Assembly handles dynamic loads up to 200 lbs.

NTB Series anti-backlash lead screw assembly is offered with flange or thread mounts. Custom nuts can be machined or molded in variety of shapes and sizes, from miniature nuts less than 3/8 in. dia to multi-function molded components with integrated nut. Manufactured with self-lubricating acetal, nut is designed to run on precision rolled shafting. Screws are 303 stainless and are available with...

Read More »

Miniature Ball Screws utilize internal ball return technology.

Miniature Ball Screws provide 95% typical efficiency. Standard diameter starts at 4 mm, with 1 mm lead, and will include 6 mm and 8 mm diameters as well. Manufactured as both rolled and ground units, ball screws come in precision classes from ISO3 to ISO7 (0.012/300 mm to 0.050/300 mm). They have nylon wipers to protect from ingress of contamination. Units can be supplied with ends machined...

Read More »

Accelerating Composites Production with Dielectric Cure Monitoring

This white paper provides an in-depth explanation of how dielectric monitoring works, and why it's the best choice for any company working with advanced composite materials.

Read More »

Ball Screws are clean room compatible.

Ball Screws are assembled, packaged, and nitrogen purged inside laminar flow, Class 10 clean room environment. They are lubricated, bagged, and sealed to eliminate contamination and enhance shelf life. Custom clean room hollow and telescoping screws can be designed and built, in addition to stainless steel and chrome plated assemblies. Inch and metric sizes are available with preloaded and...

Read More »

Heavy Load Ball Screw incorporates Caged Technology.

Available with diameters from 32 to 63 mm and leads from 10 to 20, Type HBN ball screw uses Caged Technology to act as reservoir for lubricants and eliminate need for external lubricating system. Ball screw achieves maximum of 130,000 DN. In heavy load durability tests (118 kN load, 48 mm stroke, 3.8m/min max travel speed), Type HBN performed 1,000,000 cycles without any problems.

Read More »

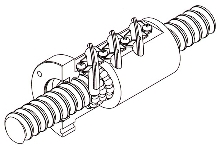

Injection Screw mixes plastic resins.

MultiMelt(TM) mixing screw produces reduced melt temperatures, faster mold cooling cycles, better mixing without degradation, and faster cycle times. Barrier type mixing section provides maximum recovery rates for most resins, including virgin, pre-colored, or color additives. Stratablend(TM) mixer is also available for intensive mixing requirements.

Read More »

Double Nut Design stops errors caused by spacers.

UNILOCK double nut design for large precision ground ball screws eliminates need for spacers or connecting hardware. Its method also eliminates backlash by using two nuts preloaded against each other and then locked using integral bonding system. With minimal number of parts, double nut eliminates angular errors in assembly of two nuts. UNILOCK system is available for ball screw diameters from 16...

Read More »

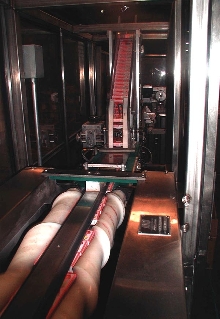

Timing Screws eliminate bacteria infiltration.

Seamless Timing Screws, constructed of FDA approved HDPE (high density polyethylene) material, are available in 16 colors and lengths up to 107 in. They facilitate sanitation and easy cleaning, making them suitable for food and pharmaceutical packaging applications.

Read More »

Timing Screws control flow of packages.

Designed for packaging industry, Timing Screws are custom engineered to orient, group and synchronize products, transition sections, and accelerate and decelerate package transfer to match existing packaging line.

Read More »

High or Low Volume Custom Crates and Boxes Available from Reid Packaging

Reid provides mil-spec crates and corrugated boxes in custom dimensions from single to triple wall and will even package them on-site. Check out the video to learn more.

Read More »