Timing Screws eliminate bacteria infiltration.

Seamless Timing Screws, constructed of FDA approved HDPE (high density polyethylene) material, are available in 16 colors and lengths up to 107 in. They facilitate sanitation and easy cleaning, making them suitable for food and pharmaceutical packaging applications.

Read More »

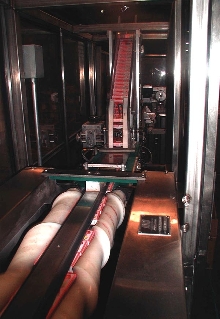

Timing Screws control flow of packages.

Designed for packaging industry, Timing Screws are custom engineered to orient, group and synchronize products, transition sections, and accelerate and decelerate package transfer to match existing packaging line.

Read More »

Designing and Specifying the Right Loudspeaker System for Emergency Mass Notification in Public Venues

A guide for designing and implementing effective loudspeaker systems for emergency situations.

Read More »

Reduce Time to Market, Improve System Uptime with Dedicated Computing Medical Solutions

Embedded computing solutions from Dedicated Computing are designed to meet unique and specific requirements. As the preferred supplier to leading healthcare OEMs, the Dedicated Computing team of expert engineers gets your product out to the market faster while helping your company avoid costly validation and verification steps. Check out our video to learn more.

Read More »