Tabletop Filling Machine offers gentle product handling.

Accommodating fill volumes from 10-5,000 ml/min, programmable Model DF32 provides automated, servo-controlled operation and performs up to 2,000 fillings/hr, depending on product viscosity. Combined pump and control unit with integrated stainless steel filling stand fits neatly onto tabletop or laboratory bench. Accuracy of Ã-

Read More »

Aseptic Liquid Filling System has semi-automatic design.

Tabletop liquid filling system, Model FP50, performs aseptic dispensing, filling, and plugging operations. It eliminates concerns caused by human operator/product interface via non-human contact filling of liquid product into vials or bottles at rates to 30 ppm. Along with peristaltic dispenser, unit features turntable infeed, in-line filling station, and rubber plug closure applicator that...

Read More »

Filling System fills bulk bags and boxes.

Material Master Powerfill(TM) Bulk Bag & Box Filler features rotating and traversing bag fill carriage. Bag support carriage and fill head lower to programmed operator height, extend toward operator, then rotate for bag strap and spout connection. Bag inflation system and densification system deliver maximum fill volume and bag stability. Box fill adapter is also available.

Read More »

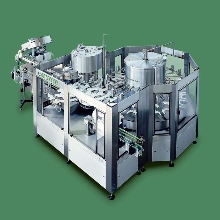

Filler/Capper feature laminar flow fill nozzles.

Carrousel net-weight filling/capping technology features laminar flow fill nozzles that provide foam-free handling of product. Unit can handle liquids from 2-16 oz at 200 bottles per minute. Wide range of filler and capper sizes are available to handle any fill volume and speed requirement.

Read More »

Bulk Bag Filler fills up to 20 bags/hour.

Automated Bulk Bag Filler provides repeatable, dust-free filling for variety of food ingredients. Standard base frame features ergonomic cantilever design that offers unobstructed access from 3 sides of machine for attaching and detaching bags. Controls include user-defined inputs that allow filling sequence to be tailored to customer's bag sizes, material, and material delivery systems.

Read More »

Double Tablet Counter comes with diagnostic software.

Made of stainless steel with polished 316 contact parts, Cremer CF1220D features 2 counting heads and 2-lane filling conveyor in 12 ft footprint. It uses IR detection, which is unaffected by dust, filling up to 110 bottle/min (based on 100-count bottles). Counter features touch-screen control panel and can be programmed with up to 300 product recipes. It handles tablets, caplets, and hard or soft...

Read More »

Bulk Bag Fillers provide repeatable, dust-free operation.

Automated Bulk Bag Fillers produce consistent, dense, and stable filled bags. Standard base frame is ergonomic cantilever design that provides unobstructed access from 3 sides of machine for attaching and detaching bags. Controls are intelligently designed to include user-defined inputs that allow filling sequence to be tailored to customer's bag sizes, materials, and material delivery systems.

Read More »Filler/Dispenser and Controller feature Ethernet interface.

Ethernet/IP Interface allows host controller to monitor filling process controlled by Model HI 3010 Filler/Dispenser. It also allows all 4 weighing channels of Model HI 3030 Weight Controller to be viewed and controlled by host. One instrument with Ethernet/IP port can act as network bridge, communicating data from other HI 3000 Series Instruments connected in Hardy-Links or DeviceNet LAN.

Read More »

Box Filler targets plastic, chemical, and food industries.

Gaylord Box Filler facilitates container filling operations, minimizing operator fatigue. It features custom inlet tube, venturi bag inflation system, gain-in-weight load cells, vibration for product compaction, and inflatable bag spout seal. Discharge of inlet tube accepts quick-connect flexible spout for Gaylord filling.

Read More »

Gas Filling Machine rapidly fills insulating glass units.

Semiautomatic Quik-Dose(TM) fills insulating glass units with liquid gas such as argon or krypton for thermal and sound insulation in times as short as 3-½ sec. Upon droplet's contact with sill edge of vented IG unit, liquid boils into gaseous state, displacing lighter, moist air. Displaced air exits through top edge's perimeter vent, while heavier gas fills from bottom-up with very little...

Read More »

Vector® Sports Training Ball Offers Visible Point of Contact

Our goal is to help every athlete derive maximum enjoyment from their sport and become a better player. We offer a line of innovative training tools that combine cutting-edge technology and out of the box thinking to deliver an unbeatable competitive advantage. The Vector® Sports Training Ball is just another example of our commitment to innovation. To learn how the Vector® is helping ballplayers everywhere, see our video.

Read More »