Bulk Bag Filler brings fill head to operator.

Swing-Down(TM) bulk bag filler has pivot-down fill head that lets operator connect empty bags at floor level. Constructed of carbon steel, unit simultaneously lowers and pivots fill head to position that places bag inlet spout connection, inflator button, and 4 bag loop latches within arm's length of operator. Remote console houses controls to raise and pivot fill head, inflate bag, open flow...

Read More »

Bulk Bag Filler has rotating/traversing bag fill head.

Material Master(TM) PowerFill(TM) FIBC Filling System has rotating and traversing bag fill head that, along with bag support carriage, lowers and extends toward operator to facilitate bag loading. Features include powered frame height adjustment and bag strap release, inflatable spout seal, and bag inflation. Modular unit also features stainless steel load cells, fork lift portable frame, and...

Read More »

Bulk Bag Filler handles FIBCs up to 72 in. tall.

Bulk Bag Filler features extended height and adjustable carriage frame with motorized screw lift, which moves up and down to accommodate various bag heights. Gain-in-weight system, utilizing guard-protected, base-mounted load cells and programmable batch controller, accurately weighs bags to accuracy of Ã-

Read More »

Booth Filling System protects operators from fumes.

Filling system features totally enclosed filling operation and fume removal. Instrumentation and controls are located in separate area, while removable panels permit access to parts and simplify maintenance. System handles containers from 5 gal pails to IBCs and can fill up to three 5 gal pails or one 55 gal drum per minute. Product includes PC 104-based digital weightmeter with display and...

Read More »

Glass Fabrication for MEMS Applications

Micro-electromechanical systems (MEMS) can be found in nearly every industry, such as the consumer electronics and semiconductor fields. Learn more about the technology and its applications.

Read More »

Bulk Bag Filler ensures stable FIBCs.

Utilizing cantilevered, heavy-gauge, carbon-steel tubing, Bulk Bag Filler allows safe 3-sided access to bulk bag filling operations. Remote bag release, desensification, de-aeration, batch weighing, and transport conveyors are available to facilitate handling of FIBCs. Mechanical-screw, adjustable-height option allows flexibility to handle various bag sizes and helps assure properly filled and...

Read More »

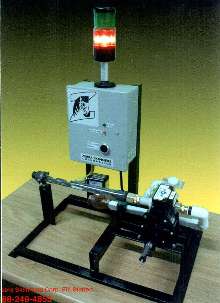

Control System automates tank-fill operations.

Zebra Auto-Fill Station(TM) mixes and meters metalworking coolants and saves labor by automating tank-fill operations. Standard features include high and low-level alarms, and triple backup systems for overfill protection. Other options include automated alarm systems, remote reporting, remote controls, and level adjustments. Station includes solenoid-driven water valve, water-driven...

Read More »

Gravimetric Filler can fill 6 pails simultaneously.

Rapid Filler features computerized flow control capability and modular design. It dispenses liquids, pastes, and other products into pails and drums weighing up to 66 lb at 2,000 pails per hour. Onboard weighing system, controlled by PC, synchronizes filling process and flow rate, and ensures filling accuracy and compliance with weights-and-measures regulations. System is suitable for...

Read More »

Bulk Bag Filler features cantilevered fill head.

Bulk Bag Filler offers pneumatically retractable bag hooks, inflatable connector to seal bag inlet spout, and feed-chute vent for dust-free air displacement during filling. Fill-head height adjustment accommodates popular bag sizes. Unit can be mounted on load cells to measure weight gain of entire bulk bag filler, or arranged with weigh hoppers suspended above for higher filling rates through...

Read More »

Change Parts work with monoblock filler/capper machines.

Monoblock Change Parts feature star wheel design that provides flexibility to isolate specific functions as needed. They combine container and bottle control with tool-less changeovers. Parts are available in variety of materials and 14 colors to meet production requirements. They can be incorporated into new monoblock filler/capper machinery or used to upgrade existing machinery.

Read More »

Filling/Closing Machine includes connection free cart.

Model AE2-CEM Net Weight Filling and Closing Machine conveys 5-gal pails to 2 different nozzles for filling, while providing high-speed weight control. Connection free cart eliminates need to plug in air or electrical lines to machine control. With no control connections, machine operates on plant air and includes automatic filter drain, self-contained flush controls, expandable conveyor,...

Read More »

Acoustic and Thermal Solutions for Original Equipment Manufacturers

Technicon's products solve the most complex noise pollution and thermal problems and improve product marketability. Check out the video to learn more.

Read More »