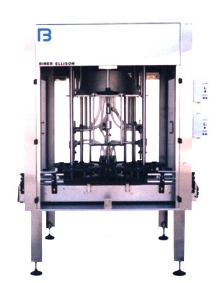

Filler offers fast, gentle filling for beverage products.

Easi-Flow operates on low vacuum/gravity filling system, which minimizes proof loss for distilled spirits applications. Pressure equalization ensures accurate fills, while low vacuum filling nozzle prevents dripping. Maintenance is minimized by employing cluster lubrication plate and cam-operated container lift platforms. Easi-Flow can be coupled with closers and pluggers, and is also available...

Read More »

Bulk Bag Filler allows bag removal with pallet jack.

Low Profile Bulk Bag Filler offers twin-centerpost design that provides accessibility to bag hooks, eliminating need for forklift. Standard units include primary bag filling components, pneumatically retractable bag hooks, inflatable cuff, and double wall product inlet port with air-displacement outlet port. Manually adjustable fill head accommodates bags from 36 to 72 in. high. Frame is...

Read More »

Filling System is offered in expandable frame sizes.

Digifil In-Line modular filling system handles fill volumes from .1 ml to gallons. Fluid capabilities include free flowing, viscous, and molten products. Designed for tool-less changeover, system features menu-based control system that automatically reconfigures filler operations across variety of parameters. Dockable Clean-In-Place and Cleanamatic(TM) automated options simplify clean up.

Read More »

Servo Auger Filler includes touchscreen interface.

nano-Filler dispenses 25 to 1000 mg of powder and granular products into rigid and flexible containers or capsules. It fills volumetrically or can be integrated with balance for fill-by-weight operation. Designed for applications in pharmaceutical, cosmetic, and chemical industries, nano-Filler can be integrated with in-line or rotary index turret equipment. Tooling for specific products and...

Read More »

OPTICS IN THE SEMICONDUCTOR INDUSTRY

This white paper provides an in-depth overview into optics in the semiconductor industry.

Read More »

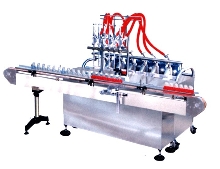

Liquid Filling System accommodates 6 to 36 fill stations.

Economy Rotary Top Drive Filling System is suitable for all free-flowing, non-carbonated liquids including food, beverages, cosmetics, and chemicals. It provides foam control, easy height and fill-level adjustment, and quick-change recirculating nozzle. Power transmission and timing-screw assemblies are positioned on top of machine, keeping important components away from wetted areas.

Read More »

Barrel Loaders enable air-free loading of syringes.

Barrel Loaders are available for 1/10th gal and 12 oz cartridges. If fluid is supplied in larger containers, one 12 oz cartridge can be filled to provide quick load of syringes before re-filling. They are available in manual versions or for connection to automatic dispensers. DSP501A Dispenser Controller sends timed air pulse to cartridge containing bulk fluid for consistent loading of multiple...

Read More »Liquid Filler prevents spillage and waste.

Model ILF-6 six station piston filler uses sanitary 316 stainless steel for all wetted components. It has stainless steel frame, safety switches, and jam proof nozzles. Nozzle adjustments and container changeovers can be made in 5 minutes, without tools. Product spillage is virtually eliminated with no bottle, no fill check.

Read More »

Sentry Equipment Introduces New Compact Hygienic Automatic Sampler

As a leader in industrial sampling equipment at Sentry Equipment, our success is built on a history of innovation and designs that epitomize value and efficiency. The new Hygienic Automatic Sampler is another example of our dedication to developing quality engineered products. To learn how this product can streamline the sampling process for dry, free-flowing materials, see our new video.

Read More »