Narrow-depth Axial Fans feature axial depth of 3-4.5 in.

Offered in 17.5–25 in. diameters, PMAX3™ Fans are engineered for applications with restricted space that require high static pressure, such asÃ- off-road equipment. Modular units are available in 3-, 6-, or 9-blade configurations with pitch angles from 20–47.5Ã-

Read More »

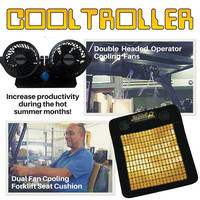

Cooling Seat, Fans keep forklift operators safe from summer heat.

Placed on seat or back of seat, COOLTROLLER Dual Fan Cooling Forklift Seat Cushion moves air continuously to cool driver's bottom or back. This 16 x 16 in.- seat features 2 input fans and heavy-duty bamboo platelets for dispersing air. Mounted to overhead guard in front, behind, or beside operator, 8 x 3.5 x 5.5 in. COOLTROLLER Double Headed Operator Cooling Fans- have low-noise (

Read More »

CPU Coolers feature pulse width modulation.

Compatible with IntelÃ-® LGA1366 type CPUs up to 85 W, Freezer 120 Series is available with pulse width modulation, with fan speed changing automatically, based on CPU loading activity. Fan speed operates within range of 800–4500 rpmÃ- with maximum airflow of 27.02 cfmÃ- and noise range of 0–39 dBA. Measuring 90 x 90 x 26.5 mm, coolers have 2 ball bearings and are rated for 12 V...

Read More »

AC and DC Cooling Fans protect electronic components.

AC (100–125 Vac) and DC (12 and 24 Vdc) cooling fans protect electronic components by keeping them at optimal operating temperature to prevent harmful thermal variances and premature failure. While AC fans provideÃ- constant flow, DC fans can run at variable speeds. Offered 5 sizes fromÃ- 40 x 40 mm toÃ- 120 x 120 mm, fans feature thermoplastic (DC) and die-cast aluminum (AC)...

Read More »

Hemp: An Eco-friendly Substitute for Cotton and Petroleum-based Synthetics

To learn more about hemp's history, composition, performance, and its sustainability and cost, download this white paper now.

Read More »

ADP Direct Drive Panel Fans

Continental Fan's all welded ADP Direct Drive Panel Fans provide superior performance, and require little or no maintenance. These industrial fans are ideal for diverse applications such as general ventilation, power plant ventilation, factory ventilation, and more. These powerful fans are available in diameters from 12 through 60 , with capacities ranging to 57,200 cfm. The ADP fan has a factory...

Read More »

Fume Exhaust Fan can operate in diverse environments.

With nozzle design and plume dispersion that promote efficiency, Mono-Stack direct drive fan is suited for pollution abatement, re-entrainment prevention, odor control, and energy recovery at universities as well as public health, government, chemical, pharmaceutical, and wastewater treatment facilities. Features include wheel sizes from 18–36 in., airflow capacities to 24,000 cfm, ESP to 8...

Read More »

Modular Plug Fan suits supply and return applications.

Suitable forÃ- OEM applications where plenum air circulator is required, TEK Plug Fans feature injection molded GRP polyamide TEK backward curved airfoil (BCA) wheels. Impellers combine precision injection molding with high-strength plastics, and integral mounting panel allows for air circulation in plenum while keeping TEFC industry-duty motor external to air stream. Featuring modular...

Read More »

Poultry Plant Now Cooler through the Upgrade of Local Technologies

Australian made equipment supplied by air movement specialist Fanquip has formed an integral part of a major upgrade at a poultry processing plant, overseen by contractor Protective Fabrications. A quantity of 84 plate axial exhaust fans were installed by Protective Fabrications to upgrade a holding area of this poultry processing plant where stock is cooled and an evaporative process takes...

Read More »IP55 AC Fans withstand harsh and rugged environments.

Cooling fan models OA109, OA172SAP, OA172SAPL, OA180, OA225, and OA280 are available in versions for applications where dust, moisture,Ã- or other contaminants might come into direct contact with fan. Along with IP55-rated sealing for safe, reliable operation and extended service life, fans feature diecast aluminum frames and dual ball bearing system.Ã- Additional featuresÃ- include...

Read More »

Ductless Fume Hoods suit electrostatic-sensitive applications.

Available in 30, 42, and 54 in. widths, AuraÃ-® ESD ductless chemical fume hoods protection against toxic fume exposure. EverSafe II™ microprocessor safety controller monitors and adjusts fume hood face velocity to user preset value, maintaining ideal containment of potentially toxic gases and vapors, while electrostatic dissipative features prevent static build-up and discharge. ASHRAE...

Read More »

Eliminate Expensive Repairs with the Hot-Shot Pipe Thawing Machine

The new Hot Shot Pipe Thawing Machine delivers an innovative and highly effective approach to thawing frozen pipes. Easy to use and versatile, it is loaded with robust features that further suit it to many challenging environments. To learn all about it, see our video.

Read More »