Freeze Dryers suit pilot research applications.

Developed with choice of options and add-ons, Genesis Freeze Dryers can be designed to meet specific application needs. Units feature chemical-resistant, 316L stainless steel chamber shelves and condenser chambers, and 4 in. dia vapor port. Optional 8 in. dia port is available to simulate production scale-up configurations. Range of control options are offered, from manual controls to cGMP data...

Read More »

Refrigerated Air Dryers eliminate moisture and contaminants.

With flow capacities from 10-425 cfm, CR SERIES maintains consistent 38Ã-

Read More »

Heated Gas Dryers handle gas flows up to 1.5 Lpm.

Series MD(TM) Dryers combine NafionÃ-® technology with heating element to dry hot, wet, sample gases prior to analysis. Nafion technology selectively removes only water from samples gases, leaving rest of gas sample unaffected. Dryers remove water directly from vapor phase, preventing loss of water-soluble gases through dissolution in condensate. Available for use with 110 or 220 Vac, or 12...

Read More »IR Dryer suits adhesive curing and drying applications.

DryIRÃ-® Model 6040 concentrates IR heat directly to desired area, resulting in immediate evaporation. Designed for drying applications that require clean, responsive, non-contact heat source on target areas up to 4 in. wide, IR energy emitted from each heater can be adjusted to match specific heating requirements. Featuring modular construction, air-cooled unit incorporates digital power...

Read More »

Glass Fabrication for MEMS Applications

Micro-electromechanical systems (MEMS) can be found in nearly every industry, such as the consumer electronics and semiconductor fields. Learn more about the technology and its applications.

Read More »

Drying Device dries all types of slurries.

Machine combines mechanical dewatering system and thermal drying device in one compact unit. Cake drying device is constructed with polypropylene membrane filter plates, which can be retrofitted for existing presses. Drying system is available in side bar and overhead beam designs for semi-automatic or fully automatic presses. Features include honeycombed, insulated heating elements and suction...

Read More »

Fluid Bed Processors are offered on rental basis.

Fluid Bed Processors feature circular configuration that enables entire system including heater/cooler/moisturizer, blower, and dust collector to be self-contained on frame with casters, ready to plug-in and run. Inherent strength eliminates need for heavy-gauge walls and cross braces otherwise required to withstand continuous vibration. Ranging in diameter from 18-24 in., rental units feature...

Read More »

Compressed Air Dryer provides continuous operation.

Scalable, modular Model MVP-HD removes moisture at point-of-use. It is based on technology that uses molecular sieve in desiccant cartridge. Each cartridge alternates between cycle of air-drying and regeneration. Desiccant life is indefinite and replacement is only necessary should it become contaminated.

Read More »

Conveyorized Coater/Dryer offers speeds up to 20 ipm.

Model 4246 dip coater and infrared dryer system dip coats printed circuit boards in protective conformal coatings, and dries coatings at rates between 2-20 ipm. Stainless steel dip tank includes recirculation and filtration system to maintain quality of conformal coating. Dryer section consists of 6 Glenro Radplane(TM) Series 36 low-temperature electric infrared heaters, which are regulated in...

Read More »

Predryer handles woven fabrics before they enter tenter.

Gas Infrared Predryer, measuring 11 x 7 x 4 ft, predries dyed woven fabrics from 52-65 in. wide before they enter main tenter range. Ten Radplane(TM) gas infrared heaters, rated at 332,904 BTU/hr each, are mounted on 2 vertical structural steel frames to form 2-pass gas infrared oven. Insulated, adjustable reflectors at predryer's entrance and exit minimize ambient air infiltration. Electrical...

Read More »

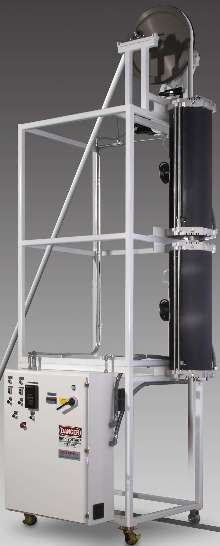

IR Curing Tower improves manufacturing of medical tubing.

Infrared tower uses 2 Radround(TM) short wave IR heaters and drive system to cure silicone tubing at adjustable rates. Heaters have clamshell design and consist of rapid-response T3 lamps. Focused, 91.2 kW IR heat ensures tubing reaches green strength. Ready for product processing almost immediately on power-up, it cools fast enough so that product is not damaged when line stops. Parabolic...

Read More »

What Can Test Devices Spin for You?

Test Devices helps you ensure the safety and efficiency of your high performance machines with cutting edge spin testing, rotor engineering, and precision balancing capabilities. Check out the video to learn more.

Read More »