Efficiency Leap With IR Drying - Drying of Water-Based Coatings

Drying of Water-Based Coatings New research on the application of IR dryers to water-based varnishes indicates high energy cost savings. With correct selection of the radiation source the infrared energy requirement for the drying process can be reduced by up to 50%. Water based varnishes are well known in various printing processes and their usage is growing. The printing industry uses these...

Read More »Drying Water-Repellent Coating - Infrared Heating on the Manufacture of Outdoor Clothing

A carbon infrared system is helping to increase production line speeds by providing pre-drying of a water repellent coating applied to a specialized fabric used in the manufacture of outdoor clothing. Moreover, its ease of control is also ensuring that there is no damage to the fabric caused by over-heating. The best outdoor clothing provides double protection to rain, as a water repellent...

Read More »Fast Drying Color Stain on Wooden Panels - Heraeus in the Wood Industry

Medium wave infrared emitters for wood industry Saunderson's Furniture Ltd, has installed an infrared dryer to assist in the color staining and lacquering of wooden panels used in the manufacture of its wide range of high quality furniture. The Kilbirnie factory produces finished items such as hi-fi cabinets, directly from bare timber. This timber, in panel form, must be color-stained and UV...

Read More »Hot Foil Embossing - Infrared Increases Running-Speed

Carbon Infrared emitters increase running-speed A carbon medium wave infrared system is helping API Foils Ltd to achieve greater line running speeds and better heating control in the hot embossing of holographic foils. API Foils is a worldwide group which produces an extensive range of stamping foils used on a wide variety of products from stationery to wine labels and from flexible food...

Read More »

Rack System Design & Buyer's Guide

There is plenty to consider before setting up or replacing storage rack systems in your warehouse. This whitepaper contains a guide and general checklist of the most important considerations.

Read More »

Fluid Bed Dryer/Granulator/Coater produces uniform results.

With HDGC Fluid Bed Dryer-Granulator-Coater, all functions can be performed in one product container. HDGC Fluid Bed features Diskjet air distribution plate for thorough, uniform mixing and fluidization of batches. Tangential, high-velocity exit of process air prevents sticking/clogging and container dead zones. When granulating, particle size can be controlled/reproduced by selecting specific...

Read More »IR Brings New Light to Manufacturing

The Processing of Metal Coatings Consumers of coated metal, wood, paper, glass, plastic and textile products are demanding attractive, long-lasting, wear-resistant surfaces. At the same time, stricter safety and environmental standards are forcing manufacturers to look at new types of finishes, e.g., water- based and powder coatings, and at different technologies to process them. Among the...

Read More »

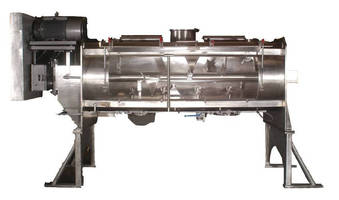

Jacketed Vacuum Dryer has easy-to-clean design.

Horizontal PloughshareÃ-® Jacketed Vacuum Dryer is designed for manufacturers who are concerned with cross contamination from batch to batch in their operation due to allergens, flavors, colors, and formula changes. Full access door across front of jacketed vacuum dryer provides access to perform frequent cleaning operations. Units are capable of taking products from liquids to dry powders.

Read More »Dryer-Dehumidifier-Cooler processes bulk solid materials.

Intended for 3-A and USDA applications as well as applications involving contamination-sensitive materials, Rotary Batch Dryer-Dehumidifier-Cooler features all-stainless contact surfaces, continuous polished welds, and external removable seals. Configurations are available for both direct and indirect drying, dehumidifying, and cooling. Offering usable batch capacity of 20 cu-ft and total...

Read More »Revolutionary Hand Dryer Now Available from Cannon Hygiene USA

Cannon Hygiene USA introduces the Dyson Airblade-which dries hands in just 12 seconds making it the fastest most hygienic hand dryer available. Additionally, the Airblade is: o Cost Effective: Delivers cost savings of nearly 98 percent compared to paper towels o Energy Efficient: Uses up to 80 percent less energy than conventional hand dryers o Hygienic: HEPA filtered to remove bacteria from the...

Read More »

Batch Mixer dries/dehumidifies/cools bulk solid materials.

With all-stainless contact surfaces and suitable for 3-A and USDA applications, Rotary Batch Dryer-Dehumidifier-Cooler uses diagonal, vertical tumbling and spilling motion to optimize particle exposure. This, along with lifters inside drum, minimizes material degradation and promotes process efficiency. Lifters also serve to direct material into discharge spout for 100% evacuation. Ingredients...

Read More »

More performance and functionality for Sinumerik 828D CNC

Siemens new SINUMERIK 828D ADVANCED, SINUMERIK 828D and SINUMERIK 828D BASIC sets the standard for productivity enhancements of turning and milling operations on standardized machines and simplify the automation of grinding machines. See our video to learn all about it.

Read More »