Slicer Wheel handles heavy-gauge metals.

ChoiceCuts(TM) Super-Slicer Wheel provides increased cutting speed and minimal burr when cutting hard and heavy-gauge metals, such as stainless or abrasion-resistant steels, high-tensile alloys, chrome, and hastelloy. Aluminum oxide Type 1 cut-off wheel is available in 4Ã-½ and 6 in. versions. Rigid cutting wheel is 0.045 in. thick and coated with blended grain that provides up to 300%...

Read More »

Cut-Off Wheels offer minimal burr.

Aluminum oxide Type 1 Original Slicer wheels provide optimum combination of abrasives, resin, and blade thickness for individual applications. Available in 4Ã-½ and 6 in. versions, wheels employ abrasive/resin formulation that increases wheel life. It is designed for speed and load typically associated with general-purpose, light-duty use. Matching system helps reduce tool vibration during...

Read More »

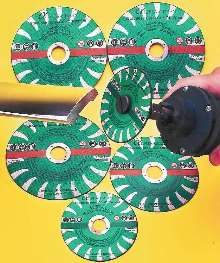

Stainless Steel Cut-Off Wheels have thin profile.

Measuring .040 in. thick, ALPHA-GREEN Stainless Steel Cut-Off Wheels feature proprietary reinforced resinoid bonding system of 60 grit aluminum oxide abrasives. They are available in Type 1 straight-sided and Type 27 depressed-center styles and come in 3, 4, 4Ã-½, 5, 6, and 7 in. sizes. Long-life cut-off wheels, also offered in 46 grit .045 in. thick version, are suitable for cutting...

Read More »Cut-Off Wheels have extra-thin, reinforced design.

Quickie Cut(TM) Type 27 wheels, for right-angle grinders, come in zirconia/aluminum oxide in Ã-½, 5, 6, and 7 in. diameters. White aluminum-oxide/stainless steel wheels are iron free to prevent rust from developing and come in 4 Ã-½, 5, and 7 in. diameters. Aluminum-oxide version, for use on aluminum, is available in 4 Ã-½ in. diameter. All are 0.045 in. thick with 7/8 in. arbor...

Read More »

Reshoring in Metal Stamping

This white paper provides an overview into the reshoring of metal stamping and other manufacturing processes.

Read More »Cut-Off Wheels offer long life.

Zip(TM) Wheels produce faster cuts to yield cooler material, even after numerous cuts, and 50% longer life over previous models. Extra-thin design minimizes cutting resistance. Applications include steel and stainless steel.

Read More »Cut-Off Wheels work with right-angle grinders.

Available in sizes from 4 to 7 in., thin Quickie Cut(TM) Type 1 wheels are offered in 2 versions: 0.040 in. thick flexible bond wheels and 0.045 in. thick rigid wheels. Quickie Cut flexible models suit applications where it is necessary to reach tight corners or get underneath nuts and bolts. Designed for use on steel and stainless steel, wheels can be used in applications for manufacturing,...

Read More »

Cutting Wheel offers design for extended life.

Slicer Plus has 2 layers of fiberglass to stiffen wheel and ensure accuracy throughout cut. Wheel has ceramic-coated, abrasive-grain formulation and measures .045 in. thick. Slicer Plus cut-off wheel is available for 4 1/2 and 6 in. capacity, right-angle grinders. It is suitable for use on stainless steel, high-carbon steel, and high-tensile strength alloys, as well as cutting partially embedded...

Read More »

Complete Water Solutions Offers Wide Range of Water Treatment Equipment

Complete Water Solutions provides full installation tailored to your water treatment needs. Check out the video to learn more.

Read More »