Loop Tunnel Parts Washer provides multi-stage cleaning.

CellMate 200 return-to-front conveyor parts washer includes aqueous spray washing and heated air drying in small-footprint package that has fork lift channels or caster for relocation. Overall dimensions of basic stainless steel machine are 37 x 78 in. Complex components may be fixtured on conveyor to facilitate targeted impingement of spray blow-off nozzles onto hard-to-clean or hard-to-dry...

Read More »

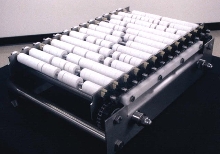

Conveyor suits food industry applications.

Easy Clean Slip-TorqueÃ-® Conveyor has both USDA and BISSC criteria incorporated in design and construction. Stainless steel, bolt-together frame has 45Ã-

Read More »

Feed System can be trailered anywhere.

QT-70 has three 24 in. x 70 ft Quick Transfer Conveyors and three 9 x 14 ft hoppers that can be separated for different applications. Its removable axle assembly and removable fifth wheel hitch are interchangeable, allowing producers to move several feed systems with one axle and one hitch. Conveyors do not require supports while transferring material. Hoppers have adjustable flow gates and...

Read More »

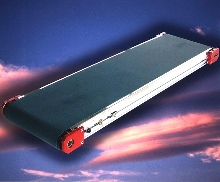

Belt Conveyors suit high-production applications.

System GUF-P 2000 conveyors come with rubber, synthetic, or plastic belts, and are supported by stainless steel slider bed. Both flat and inclined models are available with head end drive for one-directional travel, or center drive and take-up arrangements for reversible operation. Standard constant speeds are 3.3 to 263 fpm, and standard variable speed ranges are 10 to 49 fpm and 49 to 164 fpm....

Read More »

Advantages of Using Robotics in Manufacturing to Attract and Retain Skilled Workers

This white paper provides an overview into the advantages of using robotics in manufacturing to attract and retain skilled workers.

Read More »

Indexing Conveyor places parts in position pneumatically.

PCF30 and PCF50 conveyors for light part assembly automate part transfer and load/unload procedures. They index their belts into position via air cylinder. Having no motor means they can be used in hazardous environments. Belt widths are available in 150, 200, 300, 400, and 500 mm sizes. Lengths are from 250 mm to 2000 mm. Typical applications include conveyors, slides, grippers, pick and place...

Read More »

Skid Conveyor minimizes floor space requirements.

Compact floor skid system allows easy access to load for assembly operations and does not interfere with process equipment. Dual track conveyor provides stable load handling, allows in-line accumulation, and offers variable work height. Drive options include sprocket-driven or composite belt; traditional steel chain drive; or vulcanized steel cord rubber belt drive. Applications include...

Read More »

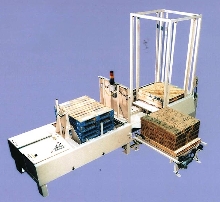

Load Transfer System provides high-speed trailer loading.

Load Transfer Station uses configuration that combines pallet stacker, pallet dispenser, and output conveyor. It provides trailer-loading at speeds up to 50 loads per hour. Pallet dispenser handles 20 GMA pallets or 17 CHEP pallets. Single driver can feed loads to LTS while, simultaneously, forklift can pick up loads coming off output conveyor. Rugged construction withstands punishment of...

Read More »

Conveyors offer 1 or 2 adjustable pivot points.

LPZ Series provides load capacity up to 1,000 lbs and maximum conveyor speed of 600 fpm. Conveyors are available in widths from 6 to 48 in. in 2 in. increments, and come in any distance in 1/8 in. increments. They include sealed bearings, T-slots for mounting of accessories, and optional V-guided belts for no tracking adjustments. Applications include packaging, plastic molding, metal forming,...

Read More »Rail System moves heavy loads.

Superail, with heavy-duty, double ball bearings, moves heavy bins, containers and tooling dies through conveyor line. Standard 4 ft section has load capacity of 48,000 lb. Floating bearings compensate for uneven or damaged containers, allowing load to roll smoothly. Self-cleaning open track allows for continuous operation without lubrication. Optional pneumatic braking system brings load to...

Read More »

Conveyors handle up to 1,000 lb loads.

Series 3200 conveyors are available in widths between 6 and 48 in., and in any length. They have load capacity up to 1,000 lb, sealed bearings, optional V-guide tracking, and maximum conveyor speed of 600 fpm. Applications include sortation, packaging, print/labeling/marking, automated and manual assembly, rubber and plastics, chemical and allied products, electronics, and medical equipment.

Read More »

How SpinSelect Can Save You Time and Money

Thanks to the unique SpinSelect™ Multi-Pocket selectable quick change tool holder, it's time to rethink the range, complexity and volume of parts that your lathe can produce. Our Spin-Select™ tool was created to increase productivity and consistency by decreasing downtime associated with lathe cutting tool and insert setups or changeovers. This product is a game-changer for the industry and we're pleased to show you why.

Read More »