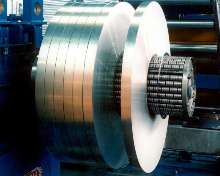

Core Slip Rewinding System provides constant coil tension.

Slip Tech system consists of core winding surface made entirely of bearings, which reduce friction between core surface and winding drum. This eliminates excess tension in individual rewound coils during build up, resulting in ability to maintain consistent coil tension because each strip is independently tensioned from core to finished coil OD. Product can also eliminate need for looping pits in...

Read More »

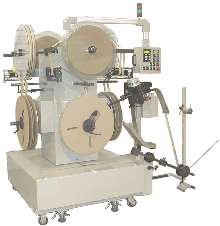

Multi-Spindle Winder offer max line speed of 500 fpm.

Modular Model MS 104 runs either independently or series-coupled with other modules to control entire take-up line. Each module contains 20 moving parts, and all components are accessible from front or rear of unit. With standard tension of 8-32 oz, winder handles packages weighing up to 80 lb and measuring up to 18 in. diameter and 12 in. wide. Adjustable traverse assembly and lay on roller...

Read More »

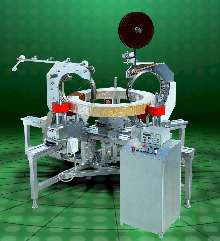

Computerized Camless Coiler offers max speed of 300 fpm.

By entering selected pattern via touchscreen interface, Model 298 produces single pancake, multi-layer, and helical coils. It features 3 driven, single-groove tooling rolls, one of which is a variable position bending roll for shaping coil. Finished coils are deposited onto receiving table, which can then be off-loaded by operator. Unit produces coils with minimum ID of 16 in., maximum OD of 51...

Read More »

Multi-Reel Rewinder is suited for small floor spaces.

Wyndmaster 348 consists of fully automatic, 8-reel take-up that can be used with any product strip up to 3 in. wide and any reel diameter up to 30 in. It uses 4-position horizontal indexer with 2 reels at each position and receives product at speeds to 600 ipm. Features include paper interleaf operation, tangential feeder, and automatic sample strips with programmable length. Changeover is timed...

Read More »

Laser Cutting

In this eBook, you'll learn more about how laser cutting works, as well as the benefits and applications

Read More »

Coil Winding Machine winds transformers rated up to 100 KVa.

Model 9204 accommodates work as large as 50 in. OD x 12 in. high. Modular design comprises powered winding and taping heads as well as 3 work rotation rollers and support rollers, each with their own gear motor. Machine handles round solid wire up to AWG 3 and rectangular wire up to 1/8 x -¾ in. Taping head winds polyester and Nomex tape as wide as 1-½ in. Model 9204 allows toroidal...

Read More »

Wire Twister handles wires with or without connectors.

Wire Twister can twist wires up to Ã-¼ in. OD or two 16 AWG stranded wires. Twisting is completed without damaging conductors. Speed control and counter provide consistent number of clockwise or counter-clockwise twists. Units are electric foot-actuated and are available with custom twisting heads.

Read More »Spindle Winder controls line speed in annealing applications.

Model S109 features mechanical traverse and pitch adjustments for set up and fine tuning. It handles package size of 24 in. dia and 12 in. width at up to 80 lb. Bolt on dancer system provides speed control, and counter weight provides tension. Speed Tension Control ensures uniform line speed and constant tension throughout spool, minimizing product damage. Standard tension range is 8-32 oz with...

Read More »

Take-Up suits high speed stamping processes.

Wyndmaster 324 incorporates 4-reel operation with side-by-side reel design, which allows machine to operate with both single strip and dual strip processes. It can function in both overwind and underwind mode. Machine can be programmed to operate with varying sizes of stamped parts, and up to 100 programs can be saved and protected with password. Motorized tangential feeder uses horizontal and...

Read More »

Solder Redefined

Indium Corporation has developed a new twist on traditional solder by developing a composite with a reinforced matrix internal structure. The result is a solder with increased strength and reliability. Check out this video to learn more about the mechanics behind the groundbreaking technology.

Read More »