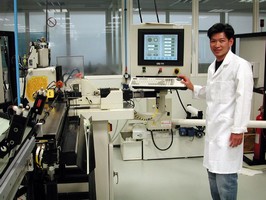

Centerless Grinder features Fanuc Powermate I D control.

With Fanuc control, Model CNC 1 is capable of storing program parameters for many different part numbers while also controlling Constant Surface Speed option. Fanuc CNC controls the combined Regulating Wheel and Work Rest slides via brushless digital servo drive motor with encoder positioning feedback. Slide movement is actuated via planetary roller satellite screw offering 2 mm pitch. Model CNC...

Read More »Royal Master Introduces CNC Wheel Dressing and Robotic Loading on Centerless Grinder

OAKLAND, NJ, JUNE 13, 2006: Royal Master is proud to introduce Our Hi-Accuracy Centerless Grinder with CNC Dressing and Robotic Loading. Built around the Lights Out Concept this machine can retrieve parts from a turning center, or vibratory bowl. The Loading and unloading can be customized to customer requirements. Some popular options are parts washing and gauging stations, or palletizing of...

Read More »

Royal Master Introduces Lights Out Centerless Grinding

OAKLAND, NJ, JUNE 13, 2006: Royal Master is proud to introduce Lights Out Centerless Grinding at IMTS 2006. The Royal Master Booth 6628 will have two machine models grinding product with capabilities of grinding up to 72 hours unattended. Using the internet, and PC Controls, your company can remotely access the machine from anywhere in the world, on any windows device such as a PDA or Laptop...

Read More »Centerless Belt Grinder uses abrasive or fiber belts.

Used for external cleanup and finishing of material Ã-½-4 in. diameter, 3 in. Model CG 3 can be converted to traditional grinder. Power head has feed rate and pressure controls and is easily adjustable. Grinder includes integrated coolant system to control sparks and dust, and can provide variety of finishes on materials ranging from aluminum to stainless steel.

Read More »

The Top 5 Major Benefits of Using Injection-molded EVA Foam for Designing Products

When considering the type of materials to use for an innovative new product, there are many factors to consider, including material quality, design flexibility, production timelines and costs. Suffice it to say that manufacturers need to strike a delicate balance between performance and profitability.

Read More »Grinder offers centerless and between-center grinding.

Kronos L dual features 2-in-1 setup where workpiece is first ground between centers at material removal rate of 0.05-0.10 mm/min on dia. Workpiece is then released, and finish grinding takes place via centerless grinding between control wheel and workrest blade. Double-end supported grinding wheel spindle permits surface speeds up to 120 m/sec, and double-end supported regulating wheel spindle...

Read More »

Centerless Grinder suits precision production processes.

Able to use conventional or superabrasive wheels, all-electric Viking SuperSeries II incorporates Landis 6400 CNC PC-based, open-architecture control system in addition to digital servo controls and SERCOS interface. Sealing arrangement for anti-friction spindles prevents ingress of contaminants. Machine accommodates parts from 0.05-2.4 in. in diameter and has 20 hp grinding wheel drive. Unit...

Read More »

Electric CNC Grinder suits high-production applications.

Viking SuperSeries II CNC Centerless Grinder incorporates Landis 6400 CNC PC-based, open-architecture control system, which is hardware-independent. Featuring digital servo controls with SERCOS interface and sealed anti-friction spindles, grinder utilizes 20 hp grinding wheel drive and accommodates parts from 0.05-2.4 in. diameter. Surface speeds range from 8,500-12,000 sfpm for conventional...

Read More »

Grinder excels on parts with perpendicular features.

CBN compatible, VikingÃ-® angular centerless grinder uses angle-mounted regulating wheel and formed grinding wheel to simultaneously in-feed grind OD and flat surface of parts while maintaining sub-micron tolerances. Plunge-type diamond roll dresser accommodates 20 in. diameter grinding wheel. Construction includes nodular cast iron and epoxy granite base, twin-grip mounted wheels, and...

Read More »

Centerless Grinder is available with Fanuc control.

Model 301 MV is built with single-piece cast iron base and bed, and has cantilever chrome grinding wheel spindle constructed of chrome and nickel plated tempered steel that runs on high-precision ball bearings. Grinding wheel spindle is driven by 7.5 kW motor. Regulating wheel headstock can be tilted + 5 deg and axially displaced, for plunge grinding of parts. It handles workpieces from 0.06 to 2...

Read More »

Centerless Grinder provides stability at stress points.

Model 305 MV grinding machine has fixed grinding-wheel head with moveable regulating-wheel slide and work-rest slide. Equipped with Fanuc CNC control, grinder is available with automatic load/unload systems and post process gauging system with compensating feedback capability. Model 305 MV handles work-piece diameters ranging from 1.5 mm to 50 mm. Maximum in-feed grinding length is 160 mm.

Read More »

ISO-Certified Plastic Injection Molding from Rodon

The Rodon Group is a proven leader in high-volume, close tolerance injection molding. We offer globally competitive, innovative manufacturing solutions for a broad range of industries. Check out our video to learn more.

Read More »