Heating Tools bend large acrylic sheets.

Series KHD evenly heats acrylic and other thermoplastic sheets to make straight-line bends for creating freestanding signs and other plastic-based structures. Tools consist of 2 rectangular aluminum bars, 2 temperature control switches, and aluminum retention units. Both bars contain electric heating element that provides uniform, continuous heat on either side of plastic sheet. Tools are...

Read More »Precision Press Brake meets high-speed production needs.

Equipped with CADMANÃ-® Express CNC control and reluctance motor, PPRM press brake is intended for bending small- to medium-sized, high-precision parts. This 35-ton machine delivers working speeds to 59 ipm and has working length of 49.2 in. Bending force is proportional with servomotor torque, which can be controlled for application, and can be reduced to 5% of max load. Features include 3.9...

Read More »

CNC, 3-Axis Tube Bender meets basic industry requirements.

Powerbend machines employ hydraulically-powered mandrel tube benders capable of handling carbon steel tube from 50-125 mm dia. With respective maximum bend angles and CLR of 180Ã-

Read More »Angle Roll bends heavy materials.

Able to operate in horizontal or vertical position, CE100 has solid steel frame fitted with conical roller bearings on all shafts. For driving power and bending speed up to 20 fpm, unit features separate drive motors for each drive shaft, which are coupled to oil-filled reduction gearboxes. Center roll is hydraulically positioned using joystick control, digital readout monitors center roll...

Read More »

Smart Pricing Labels for Smart Retailers

To learn more about ESLs and how companies like ZDA Communications can help, download this whitepaper now.

Read More »Hydraulic Press Brakes offer capacities from 90-240 tons.

With working lengths from 78-168 in., Series PPEC is offered in 4- and 5-axis configurations. Five-axis design is equipped with CNC-controlled crowning system, which ensures ram and table are parallel during bending. Standard backgauge fingers allow gauging to 39.4 in. and serve as material supports. WindowsÃ-® NT-based CADMANÃ-® Express control provides automatic calculation of bend...

Read More »

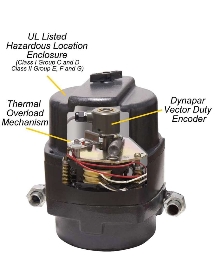

Brake features internally mounted encoder.

Smart Brake has sealed, hollow shaft incremental encoder that provides continuous feedback for speed, direction, and positioning. Information received from encoder can be fed to PLCs, vector drives, and variable speed controls. Brake is available in torque ratings from 1.5-175 lb-ft to fit NEMA C Face motors from 56C-286TC. Enclosure types include standard, waterproof, washdown, and UL-approved...

Read More »

Panel Bender suits small batch operations.

Fully automatic Performer ABTÃ-® panel bender verifies sheet thickness, tests and compensates for thermal expansion, self-adjusts for bending spring-back, and uses algorithms to compensate for material thicknesses and bend profiles to make both simple or multiple up and down bends. Digitally-powered manipulator with integrated rotator turns blank to proper angle for bending using the notches...

Read More »

Press Brakes feature PC-based graphical controls.

Available in 14 sizes from 16-2,000 tons with standard bed lengths from 4-24 ft, PROFORM Press Brakes offer Ã-

Read More »

Press Brakes deliver accurate, first time bends.

Series PR includes Integrated Process Control technology, which provides precise springback compensation and thickness measurement for processing wide range of materials and thicknesses. Pressure Reference system provides dynamic crowning, side frame deflection compensation, pressure regulation, temperature compensation, and tool overload protection. All models offer CNC control and offline...

Read More »

Hydraulic Press Brakes include CNC control options.

With models ranging from 175-3,000 tons, K-Series Hydraulic Brakes come in 8-40 ft standard bed lengths and various tandem designs. Medium-to-heavy-tonnage bending products incorporate hydraulic system with automatic decompression, precision leveling accuracy, tonnage control/overload protection, and redundant valving. With speed and ram tilt adjustments, construction limits need for die shimming...

Read More »

What Can Test Devices Spin for You?

Test Devices helps you ensure the safety and efficiency of your high performance machines with cutting edge spin testing, rotor engineering, and precision balancing capabilities. Check out the video to learn more.

Read More »