Renishaw Inc

Hoffman Estates, IL 60192

Optical Encoders deliver up to 50 nm resolution.

Models RG2 (20 Ã-µm) and RG4 (40 Ã-µm) are open, non-contact linear encoders that combine cut-and-tape steel scale with side-lit filtering optics, offering immunity to dirt, dust, and contamination. Along with choice of clocked outputs to promote controller compatibility, products feature overspeed as well as low-signal alarms. Other features include RGE and RGB interfaces and readheads...

Read More »Magnetic Kit Encoders offer compact, end-of-shaft mounting.

Based around AM256 chip, solid-state rotary encoder kits are intended for brushless dc motor control. Products, available with absolute, incremental, and analog outputs, offer resolutions from 6- to 12-bit. Non-contact, no-wear units operate in continuous temperatures to 125Ã-

Read More »Magnetic Kit Encoders offer 12-bit resolution.

Based around AM256 chip, Magnet Kit Encoders operate at speeds to 60,000 rpm and continuous temperatures to 125Ã-

Read More »Fiber Optic Laser Encoder offers 38 picometer resolution.

Providing part-per-billion laser frequency stability, Model RLE20 uses fiber optics to deliver laser light directly to measurement axis, eliminating need for remote beam splitters, benders, and adjustable mounts. System provides positional output signals in differential digital RS422 and 1 Vpp sine/cosine formats. Digital output signals provide resolutions up to 10 nm, while analog signals can be...

Read More »Scanning System facilitates CMM part inspection.

Offering measurement speeds up to 500 mm/sec, 5-Axis Scanning System integrates Renscan5(TM) 5-axis machine control, REVO(TM) measuring head, laser-corrected probe, and UCC2 universal CMM controller. Featuring spherical air bearing technology, REVO uses synchronized motion when scanning to follow changes in part geometry, without introducing dynamic errors. Two rotary axes are driven by...

Read More »

Tool Recognition System uses laser to detect broken tools.

Suited for high-speed detection in real machining conditions, System TRS1 uses Tool Recognition Technology to distinguish intact tools from broken tools including drills, taps, reamers, and end mills. Laser precision makes it effective with tools down to .019 in. dia. With operating range of 12-79 in. system can be mounted outside working envelope, and is suited for range of CNC machines, from...

Read More »

Linear Encoder System offers low thermal expansion.

Made of Invar for thermal expansion of 1.3 Ã-µm/m/K, RELM linear scale intelligent encoder offers non-contact performance with accuracy to Ã-

Read More »

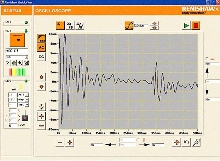

Software gives streaming data on machine dynamics.

Used with ML10 laser calibration system, QuickView software permits engineers to study minute variations in linear or angular displacements, velocities, or accelerations in machines and mechanical devices. Graphic interface allows flexible point and measure operation, while oscilloscope-type display options, combined with inherent low noise of ML10 laser, permit users to see features on screen...

Read More »

Optical Angle Encoder offers intelligent signal processing.

Signum(TM) RESM Rotary Ring Encoder delivers speeds to over 3,600 rev/min and accuracy to Ã-

Read More »

Precision Styli are suited for Zeiss CMMs.

Constructed of tungsten carbide, titanium, ceramic, aluminum, stainless steel, carbon fiber, and hardened steel, 300+ M5 styli and adaptors are offered for Zeiss analog probe systems without probe changing, measuring heads with probe changers, and dynamic probe heads. Products include straight, fine, star, thread measurement, swivel styli, and spherical disc styli. Extensions, joints, adaptor...

Read More »