Share:

Press Brake Work Support facilitates press brake job setup.

Twist-in Fast Setup Work Support system aids in setup of press brake jobs that need work support. Featuring quick clamping adjustment handles, product enables work supports to be positioned and clamped without requiring use of wrench. Separate adjustment handle for each axis allows left/right, in/out, and up/down positioning. Features include two 15 in. support arms and modular, 12 in. steel...

Read More »

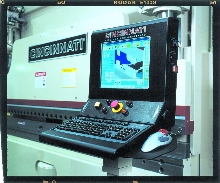

Press Brakes feature PC-based graphical controls.

Available in 14 sizes from 16-2,000 tons with standard bed lengths from 4-24 ft, PROFORM Press Brakes offer Ã-

Read More »Hydraulic Stamping Presses offer 3 minute die change.

Available in 75, 110, 175, and 250 ton capacities with 8-12 in. stroke, Series OBS allows blanking, forming, drawing, punching, and crimping, all on same machine. Hydraulic valves and electronic control enable high cycling speeds. Standard CNC controller with program storage allows accurate setups on repeat jobs. Presses accept manual or coil feed and feature virtually infinite stroke length...

Read More »

CNC Forming Center gives precision to part bends.

Autoform+ CNC Forming Center combines press brake platform with PC-based control. Bend simulation graphics provide visual instructions and guidelines, while screen displays show each step and change in part shape produced with full 360Ã-

Read More »

CNC 5-Axis Backgage offers 3,000 ipm positioning rates.

Available on 90-350 ton AUTOFORM press brakes, product features independent Z1, Z2 left-right axes suited for multi-die setups where operator must work down length of bed. Closed-loop servo drives zip gage fingers from bend to bend and provide lock-in of gage positions. Multiple programmable axes eliminate manual positioning of gage fingers and gage bars. Features include interference-removing...

Read More »

Software offers expert system laser processing.

Laser Programming and Nesting Software v3.6 can determine and select best size sheet for parts nest. It automatically performs sequencing, process optimization, and feature avoidance, and adjusts part programs and codes to each machine model's speed, acceleration/deceleration, and processing capabilities. Software allows nest file to be used by more than one model laser without rebuilding nest....

Read More »

Press Brake includes 3D graphics control.

Proform hydraulic press brake features adjustable stroke length and full-tonnage throughout stroke. Precision servo hydraulics allow unit to hold ram repeatability to Ã-

Read More »

Laser Cutting System limits changeover time to seconds.

Model CL-707 combines linear motor drive, 8 x 20 ft cutting table size, and dual-pallet design, which allow one table to be unloaded/reloaded while second table is being processed. Linear-motor axis drives exceed 2.0 G acceleration and head positioning speeds reach 10,000 ipm. Brushless linear motors, linear encoders, and CNC control deliver positioning accuracy of Ã-

Read More »Software makes air bending a standardized production technology.

Programmable Dynamic Thickness Compensation(TM) (DTC) uses on-the-fly compensation to overcome material variations. It allows air bending to be used to achieve precision, repeatable bend angles. DTC software calculates material thickness with microsecond calculation capability before each bend and automatically determines ram reversal position needed to deliver precise bend angle in 1 ram stroke....

Read More »