CNC Forming Center gives precision to part bends.

Share:

Press Release Summary:

Autoform+ CNC Forming Center combines press brake platform with PC-based control. Bend simulation graphics provide visual instructions and guidelines, while screen displays show each step and change in part shape produced with full 360° rotation. Fast Part Programming format allows jobs to be programmed, run, and edited from one screen and Autoform+ software provides calculations of ram reversal position and gage allowance values.

Original Press Release:

New AUTOFORM+ CNC Forming Centers Use Leading Edge Control Capabilities to Speed Processing and Give Ultimate Precision to Part Bends

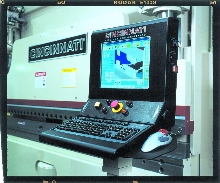

March 2004 - New AUTOFORM+ CNC Forming Centers apply advanced control technology to bring highest productivity and precision to complex or simple parts in sheet metal or plate. Cincinnati Incorporated combines the high precision and reliability of its proven AUTOFORM press brake platform with a leading edge PC-based control featuring Windows(TM) operating system and large "super sharp" 15-inch active-matrix, touchscreen color monitor. Easy-to-follow bend simulation graphics provide comprehensive visual instruction and guidelines on how to form the part. Screen displays show each step and the change in part shape that is produced. Capabilities include full 360° rotation for viewing from a different angle or perspective to clear any confusion over part handling or gaging.

Parts can be programmed off-line or at the machine. A proprietary Fast Part Programming format, created with input from experienced operators, allows simple jobs to be programmed, run and edited from one screen with minimal data entry. AUTOFORM+ software supplements the operator's knowledge with automatic calculations of ram reversal position (based on angle, material thickness and die dimensions) and gage allowance values (based on flange description).

A graphic tool library enables storing of die information, saving on setup time. The tool library stores exact tool dimensions and displays a view of the tool to help the operator to sort and select the correct tooling. It can automatically calculate tool segment combinations.

The stored tool information is used to automatically calculate ram and backgage positions, as well as limit machine tonnage to safe levels in protecting tools from damage. The automatic calculations improve setup accuracy and reduce the number of trial pieces required to make a good part. AUTOFORM+ control software also applies in-process compensations through:

o Dynamic Thickness Compensation, which enables consistent bend angles despite variations in material thickness;

o Adaptive Forming, which senses variations in material thickness and strength to automatically adjust ram reversal position.

The advanced LCD screen combines active-matrix TFT technology with XGA (1024 x 768) resolution for superior brightness and sharpness. Touchscreen input speeds job set-up by replacing keys and buttons, while a full-sized keyboard and trackball make it quick and simple to enter detailed information. A built-in Ethernet port provides connection to computer networks, allowing part programs and files to be downloaded directly from a server or transferred to AUTOFORM's large capacity hard drive. Files can also be transferred using built-in floppy disk and CD-ROM drives.

The AUTOFORM software provides three ways to produce a part - by creating a text program, by importing and converting a CAD drawing, or by creating a cross-section or flat pattern drawing from scratch. The software automatically converts the drawing into a 3D view. After material type, thickness and tools are entered, Bend Simulation calculates the possible bend sequences and graphically displays the steps. After the operator checks the simulation, the software performs post-processing to create the working program.

Engineered for exceptional versatility, the AUTOFORM+ can handle sheet metal or plate and accepts American or European tooling in forming simple or complex parts with outstanding precision. Programmable ram control enables a unique forming speed for each step in a bending sequence to optimize productivity, part quality and safe handling. This allows slow forming speeds to minimize material marking and to bend long parts without whip-up. Programmable control allows selection of angle, position and tonnage, plus use of Dynamic Thickness Compensation or Adaptive Forming as the ram reversal mode for each step in a program.

AUTOFORM + CNC Forming Centers are available in 60, 90, 135, 175, 230 and 350 ton models with bed lengths from 6 to 16 ft.

For more information on the touchscreen control and the AUTOFORM press brake line, contact: Cincinnati Incorporated, Box 11111, Cincinnati OH 45211. Tel: 513-367-7100. Fax: 513-367-7552. Email: info@e-ci.com. Web site: www.e-ci.com