Haas Automation, Inc.

Oxnard, CA 93030

Horizontal Machining Center offers 15 x 15 x 10 in. work cube.

Mini HMC features twin pallet changer and built-in 4th axis capabilities. It is equipped with 12,000 rpm, 40 taper spindle with inline, direct-drive system that couples motor directly to spindle. Ultra-fast ballscrews and high-torque servo motors on all axes provide rapids up to 2,000 ipm and accelerations to 0.75 g to reduce cycle times, and 24-pocket side-mount tool changer swaps tools in 2.8...

Read More »

Vertical Machining Center performs high-speed operations.

Super VF-2 is equipped with 12,000 rpm, 40-taper spindle with inline, direct-drive system that couples motor directly to spindle. Powered by 30 hp vector-drive system, spindle yields low-end torque and speed necessary for high-speed machining operations. Side-mount tool changer provides tool changes in less than 1.5 sec. Ballscrews and servo motors on all axes deliver rapids of 1,400 ipm.

Read More »

Machining Center provides high-speed operations.

Mill Drill Center has dual fixture stations that allow operator to load and unload parts on one fixture while machine mills, drills, and taps parts on other fixture. Servo powered gear drive changer rotates fixture stations in less than 1.5 sec to maintain nearly constant spindle time. High speed side mount tool changer changes tools in just 1.5 sec. It has work cube of 12 x 10 x 12 in.,...

Read More »

Turning Center fits into small spaces.

Mini Lathe gang-tool turning center has 5.5 x 4.5 ft footprint, 7.5 hp vector drive spindle, and air-actuated 5C collet. It accepts bar stock up to 1.06 in. Visual Quick Code programming system has graphical interface for creating simple G-code programs. Large capacity coolant pump improves tool life and allows higher cutting speeds. Optional floppy disk drive can upload programs from PC disk,...

Read More »

Turning Center features dual spindles.

TL-25 lathe allows turning of double-ended parts in single setup on one machine. It has 30 hp vector-drive main spindle with 10 in. chuck, and 8 hp sub-spindle with 5 in. chuck. Main spindle provides speeds to 3,400 rpm, and sub-spindle provides speeds to 4,000 rpm. Standard 12-station tool turret holds 6 VDI 40 tools and 6 bolt-on tools. Live tooling and full C-axis are optional.

Read More »

Gantry Router doubles as milling machine.

GR-510 offers travels of 120 x 60 x 10 in. (X,Y,Z) and 40-taper milling head. It includes 10,000 rpm spindle with 15 hp vector drive system. Automatic 10-pocket tool changer is standard. Machine's 5 x 10 ft fixed table provides support for large or heavy workpieces. CNC accepts ISO standard G-code and is compatible with major CAM systems. Built-in graphic dry-run mode allows operator to check...

Read More »

Machining Center provides drilling, tapping, and milling.

Mill Drill Center offers 12 x 10 x 12 in. work cube and 15,000 rpm 40-taper spindle, powered by 15 hp vector drive system. Ballscrews and high-torque servo motors on all axes provide rapids to 2,400 ipm and accelerations to 0.8 G. Automatic tool changer stores up to 20 tools and changes them in 1.5 seconds. Dual fixture stations allow operators to load and unload parts on one fixture while...

Read More »

Laser Systems cut accurately.

Z-1 and Z-2 Laser Cutting Systems combine rigidity and accuracy of VMC with Coherent Diamond-Series CO2 pulsed lasers. Z-1 has 100 W laser and 16 x 12 x 10 in. (XYZ) travel, making it suitable for etching, engraving and cutting small metallic and non-metallic parts. Z-2 has 500 W laser and travels of 40 x 20 x 25 in. Both are available with 4th and 5th axis, providing ability to tackle...

Read More »

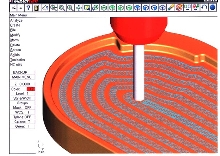

Machining Centers work in five axes.

VR Series 5-axis profiling vertical machining centers make complex shapes, undercuts, and difficult angles. Travels are 64 x 40 x 30 in. for VR-8, 64 x 40 x 30 in. for VR-9, and 120 x 40 x 30 in. for VR-11. Each has dual-axis spindle with fully enclosed gimbal to protect gears from chips and coolant. VR head provides +/-32 deg of travel on A and B axes for complex geometries and undercuts. All...

Read More »

Vertical Machining Center handles many pallets at once.

VF-3 Mini FMS has dual pallet stations, 4 pallets, automatic pallet changers, and 40-tool side-mount tool changer. For multi-op parts, each pallet can be set up to run different operation. Parts are moved from pallet to pallet for machining, rather than having to change entire machine setup after each operation. Parts can be run just-in-time, rather than by batch. Fixturing for repeat jobs can be...

Read More »