Turning Center fits into small spaces.

Press Release Summary:

Mini Lathe gang-tool turning center has 5.5 x 4.5 ft footprint, 7.5 hp vector drive spindle, and air-actuated 5C collet. It accepts bar stock up to 1.06 in. Visual Quick Code programming system has graphical interface for creating simple G-code programs. Large capacity coolant pump improves tool life and allows higher cutting speeds. Optional floppy disk drive can upload programs from PC disk, download for back-up storage, or perform DNC directly off disk.

Original Press Release:

Small Turning Center Provides Speed, Versatility and Value

Diversification is the key to survival in today's metalworking industry. In order to respond quickly to the ever-changing part mix, shops need fast, flexible and affordable machine tools.

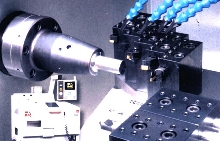

The Mini Lathe from Haas Automation, Inc., is just such a machine. It is a small-footprint, gang-tool turning center designed to fit into the tightest spaces of any bustling machine shop, yet, it delivers the performance and versatility necessary for volume production work.

The Mini Lathe features a 5.5' x 4.5' footprint and industry-unique gang-style tooling. Its 7.5 hp (peak) vector drive spindle (6,000 rpm) provides fast acceleration and plenty of torque for high-production work and part versatility. The Mini Lathe's A2-5 spindle nose (non-threaded) features an air-actuated 5C collet, and accepts bar stock up to 1.06".

The Mini Lathe's high-speed cross slide features travels of 12" x 12" (x, z), and allows mounting of up to 10 gang-style tools. The Haas-only design guarantees fast tool changes and short cycle times, and the table's unique shape offers quick setup and good clearance.

To increase the capabilities of the Mini Lathe further, an option is available for air-driven live tools. This option includes four M-code activated air-supply solenoids, all associated plumbing and two toolholders that accept standard 30 mm pneumatic tools. A combination of static and live tooling may be set up on the lathe's extra-rigid, quick-set tool platen for both standard turning/boring/threading and assorted cross-hole drilling or milling operations. Toolholders for driven tools may be mounted at any angle from 0 to 90 degrees for extreme versatility, and easy two-bolt installation allows tools to be adjusted quickly within the holder.

Pair the Mini Lathe with an automatic bar feeder and it becomes a high-production machine capable of churning out parts up to 1" diameter by the thousand. For the manual shop, the Mini Lathe's affordable price combines with the powerful, easy-to-use Haas control to make it a practical first step into CNC.

The Mini Lathe comes standard with Haas' Visual Quick Code, a proprietary conversational programming system with a graphical interface that makes creating simple G-code programs nearly effortless. A large-capacity coolant pump is available to improve tool life and allow higher cutting speeds, and adding a floppy disk drive makes it easy to upload programs from a PC disk, download for back-up storage or DNC directly off the disk. A parts catcher is available to speed production further, and the Haas Servo Bar 300 bar feeder may be added for unattended operation.