EXSYS Introduces Turning Machines and Innovative Gear Box Solutions at The Greenville Convention Center

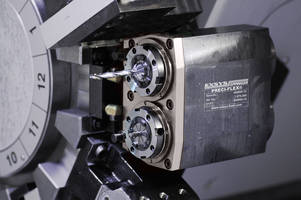

PRECI-FLEX modular tool holding system speeds turning center tooling changeovers and improves productivity with longer tool life. DECO-FLEX tooling interface adds flexible precision for small-part manufacturing and includes holders for Star CNC brand Swiss-style machines. EPPINGER BT and BM spiral bevel gearboxes provide minimized tooth clearance and optimal transmission properties.

Read More »

Face Grooving Tools operate as single or twin cutters.

Designed to fit large diameter Series 318 and Series 319 SW twin-cutter boring heads, Face Grooving Insert Holders can be used as single or twin cutter grooving tools for 2.087–118 in. diameters. Design allows for grooving depth up to .472 in., with minimum width of .079 in. and maximum of .375 in. Using boring tools as twin cutters, with simultaneous adjustment in radius and length, allows...

Read More »Snap Frame Sign Holders drive customer engagement, sales.

Offered in sizes from 8.5 x 11 in.Ã- to 30 x 40 in., classic snap frame sign holders can be used to add signage to walls, sides of fixtures, or tabletops/countertops in stores and restaurants. Clear sheet protects print materials for years, and messages can be changedÃ- as often as desired. In addition to silver or black frame, options include round or mitered corner. Hanging accessories...

Read More »

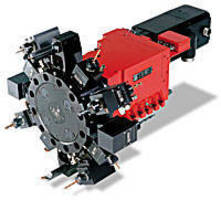

Disc-Type Tool Turrets mount in any position.

Designed for CNC lathes and turning centers, SAUTER Tool Exchanger Turrets are available in 6 frame sizes, each with non-lifting tool carrier having 8, 12, or 16 tool capacity. Bi-directional operating units are prepared for either axially mounted static tooling or combination of both static and live tooling. Featuring low kinetic design, turrets are extremely crash resistant. Optional central...

Read More »

6 Reasons to Consider Hydroforming over Traditional Metal Stamping

To learn more about the functions of the hydroforming process, the key differences from other processes, and why it is preferable over other stamping options, download this eBook now.

Read More »

Surface Mount Coin Cell Holders rise 2 mm above PCB surface.

Used for retaining No. 2032 Lithium Coin Cells securely under shock and vibration in high-density applications, polarized coin cell holdersÃ- have dual-spring contacts and may be used with vacuum and mechanical pick-and-place systems. Minimized height is made possible via method of partially mounting thruÃ- hole in PCB, allowing holder to sit through PCB. Stabilization tabs in LCP, UL...

Read More »

Stick Electrode optimizes operator control and weld quality.

Available in 1/8 or 5/32 in. diameters, Hobart 610 features concentric design, ensuring even coating along entire length and consistent arc performance. Stick electrode exceeds AWS minimum specifications by offering tensile strength of 78,000 psi and yield strength of approximately 65,000 psi. To minimize cracking in low temperatures, product offers Charpy V-Notch impact values of 45 lb-ft at...

Read More »

Hydraulic Toolholder supports milling, drilling, and reaming.

Suited for high volume cutting, TENDO E compact can safely transfer torques up to 384 lb-ft at 20 mm clamping diameter. Universal toolholder provides vibration damping and precise run out accuracy of less than 0.0001 in. at 2.5 x D, protecting machine spindle and cutting tool from damage. Common spindle connections are available, including HSK-A63, SK40, BT40, CAT40, and CAT50 interfaces.

Read More »New Identity Theft Protection

According to identitytheft.info, about 15 million Americans have their identities used fraudulently each year, resulting in financial losses upwards of $50 Billion. This means that approximately 7% of all adults have their identities misused resulting in $3,500 in losses, each year. Taken one step further, this will cost the average American $250 a year, and once every 14 years (on average) each...

Read More »

Atlas Presents Product Enhancements at the European Coatings Show 2013

Linsengericht, Germany - Atlas Material Testing Technology, the global leader in weathering durability testing equipment and services, will exhibit at the European Coatings Show (ECS), March 19-21, 2013 in Nuremberg, Germany (hall 5, booth 5-343). Atlas will feature its standard weathering instruments - the Ci4000 Weather-OmeterÃ-®, SUNTESTÃ-® XXL+ and UVTest. Among the latest...

Read More »

LED COB Array Holder promotes cooler LED fixture operation.

Fabricated from hardened stainless steel, 250 V, 4 A Chip-Lok™ LED COB (chip on board) Array Holder provides mechanical and electrical attachment for COB array manufacturers such as Citizen, Cree, LG, Nichia, and Sharp. Design helps lighting manufacturers reduce chip temperature, subsequently extending array life or allowing OEM to reduce size of heat sink. Built-in spring holds array securely...

Read More »

Material Handling Solutions from Global Leader in Rubber & Urethane Power Transmission

Megadyne's QST polyurethane timing belts take up less space and guarantee a lower noise level than chain and other traditional material handling belts. Check out our video to learn more.

Read More »