Ceramic Adhesive suits high temperature potting applications.

Magnesium oxide filled, water based, 2-part ceramic adhesive and coating system Ceramabond(TM) 672 can be used in assembly of high temperature catalytic converters for applications to 2,800Ã-

Read More »Underfill Material enables recovery of substrates and PCBs.

Manufactured in lead-free environments, LoctiteÃ-® 3536 underfill material is designed to fill space beneath fine-pitch CSP and BGA packages. It cures at low temperature which minimizes thermal stress to other components on printed circuit board and allows for in-line curing. Product protects solder joints against mechanical strains such as shock, drop, and vibration, and offers manufacturing...

Read More »

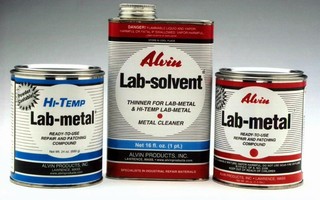

Lab-metal Repair Compounds Solve Patching Problems For Safe Manufacturer

When a U.S. safe manufacturer / fabricator recently converted from liquid coating (spray paint) to powder coating, they faced one obstacle: the two-part epoxy based fillers used to cosmetically patch and fill their rough welds and seams failed in the heat of powder coating ovens. After successfully testing Lab-metal and Hi-Temp Lab-metal, one-part metal repair and patching compounds from Alvin...

Read More »Low Viscosity Adhesive offers Tg of 90-

TRA-BOND F110 is optically clear, low viscosity adhesive. Two-part epoxy can be room temperature or heat cured, and provides thin bond line on applications involving prisms, lenses, and other optical components. Adhesive exhibits wicking and wetting characteristics, offers high strength structural bond, and bonds to glass, ceramics, metals, and most rigid plastics.

Read More »

Top 10 Industries That Benefit From Water Treatment Solutions

Learn about which industries benefit the most from water treatment solutions.

Read More »Compounds blend epoxy and graphite for strong bonds.

Two-component Grade RX offers pot life of 3Ã-½ hr at room temperature and set time of 6-8 hr without additional heat, while single-component Grade PX consists of heavy paste that must be cured for 30 min at 285-315Ã-

Read More »

Transparent Compound is suited for optical applications.

TRA-BOND 546S01 is low-viscosity, UV-curable material that exhibits minimal shrinkage during cure to minimize stress. Rigid material also has secondary heat curing system to achieve its optimal Tg of 88Ã-

Read More »Epoxy Staking Compound provides electrical insulation.

Two-part, medium-viscosity TRA-BOND 2112 offers room temperature or heat cure, and once cured, provides resistance to weather, galvanic action, petroleum products, alcohol, salts, and other organic and inorganic compounds. Solvent-free thixotropic adhesive features glass transition temperature of 93Ã-

Read More »Epoxy Compound passes NASA outgassing specifications.

Two-part, thixotropic TRA-BOND 2151 is heat conductive, electrically insulating, and can be room temperature or heat cured. Coefficient of thermal expansion allows bonds to surfaces including metals, silica, alumina, ceramics, glass, and plastics. Product is suited for staking transistors, diodes, resistors, integrated circuits, and other heat-sensitive applications.

Read More »Adhesive offers lap shear values of 3,300 psi.

Medium viscosity TRA-BOND 2101 bonds to most clean, dry material surfaces including metals, ceramics, glass, wood, leather, and rigid plastics. Resistant to many organic and inorganic materials including weather, salt solution, and many mild acids and alkalis, 2-part TRA-BOND 2101 has 30 min pot life and can be room temperature or heat cured.

Read More »

Epoxy Compound offers set time of 5-7 minutes.

High-viscosity TRA-BOND 216R01 exhibits lap shears of 3,600 psi with room temperature cure and 4,500 psi with 65Ã-

Read More »

Eliminate Expensive Repairs with the Hot-Shot Pipe Thawing Machine

The new Hot Shot Pipe Thawing Machine delivers an innovative and highly effective approach to thawing frozen pipes. Easy to use and versatile, it is loaded with robust features that further suit it to many challenging environments. To learn all about it, see our video.

Read More »