Clear Compound laminates, seals, bonds, and coats.

Single-component UV19LV bonds and seals clear films and sheets to other films, paper, and foil substrates. Uninhibited by air, 100% reactive, acrylic-based polymer composition does not emit any VOCs during cure. Mobile liquid has viscosity under 300 cps @ 75Ã-

Read More »

Epoxy Compound bonds plastic and thermoplastic substrates.

Manufactured as 2-part, low-viscosity epoxy, flexible TRA-BOND 2170T bonds all types of plastic, including nylon, PVC, polyethylene, acrylic, lexan, polypropylene, kapton, and thermoplastic substrates. Epoxy can be room temperature- or heat-cured and exhibits lap shear strength of 2,500 psi. Also available in thixotropic formulation, material suits applications in automotive, medical, aerospace,...

Read More »

Wax-Based Compound acts as invisible clamp.

Consisting of wax-based compound embedded in paper, heat-activated Mitee-Grip maintains parallelism on precision parts. It bonds to steel, aluminum, glass, ceramics, wood, and most plastics. To bond parts to sub-plate with holding force of 40 psi, Mitee-Grip is placed between sub-plate and workpiece and is heated to 180-200Ã-

Read More »

Repair Compund is designed for marine use.

Used above or below water on vessel's surface, Marine Repair Compound consists of 2-part epoxy that can be painted and sanded. Product repairs anything from fiberglass and plastic to aluminum and wood and also aids in procedures such as bolt or cleat repair and installation. It dries white and cures in 2-4 hr, depending on temperature. Also available, acrylic version is offered for making repairs...

Read More »

The Ultimate Guide to Enclosed Tubular Drag Cable and Disc Conveyors

This whitepaper provides a comprehensive overview of enclosed tubular drag cable and disc conveyors.

Read More »

Epoxy Adhesive creates electrically insulating contacts.

Tra-Bond 816H02 is suitable for stacking transistors, diodes, resistors, and integrated circuits to PCBs. Rheology of adhesive allows it to stay in place once dispensed. It bonds readily to metals, silica, steatite, sapphire, ceramics, glass, and plastics. It can be cured at room temperature to Shore D Hardness of 90 and has working life of 1.5 hr.

Read More »

Repair and Patching Compound is offered in caulking tubes.

Single-component, aluminum-loaded Lab-metal hardens by exposure to air into sandable, grindable, tappable metal. Dent filler withstands temperatures to 350-°F or one-time exposures to 425-°F. Ready-to-use metal putty is also available as Hi-Temp Lab-metal, which withstands temperatures to 1000-°F. Packaged in 20 oz caulking tubes, product seals seams and other specialized applications.

Read More »

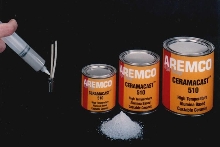

Encapsulant/Potting Material exhibits

Ceramacast(TM) 510 aluminum oxide based, hydraulic-setting ceramic compound potting material can be used to encapsulate cartridge heaters and embed high temperature components to 3200Ã-ºF. Supplied as dry powder, Ceramacast 510 is bonded using calcium aluminate and as-cast. Its dried density is 180 lbs/ft3, and it exhibits exceptional thermal conductivity and dielectric strength of 75-100...

Read More »

Standex Engraving Mold-Tech Offers Nickel Shell Capabilities on a Global Scale

Standex Engraving Mold-Tech is the premier, global supplier for mold texturing and surface finishing. With a full range of services, Standex Engraving Mold-Tech is also the only nickel shell supplier producing in three global locations. See our video to learn more.

Read More »